- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

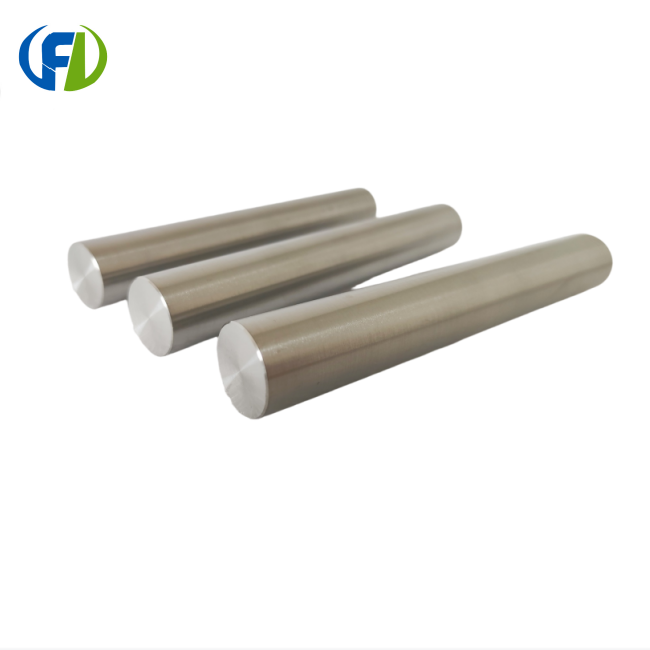

What Makes Niobium Rods Essential for High-Temperature Environments?

In the realm of high-temperature applications, niobium rods have emerged as indispensable components due to their exceptional properties and performance. These versatile metal rods play a crucial role in various industries, from aerospace to nuclear energy, where extreme heat resistance is paramount. This article delves into the unique characteristics that make niobium rods essential for high-temperature environments, exploring their protective coatings, performance in vacuum furnaces, and thermal expansion properties.

Protective coatings for niobium rods in extreme heat

When it comes to withstanding extreme temperatures, niobium rods excel. However, to further enhance their capabilities, protective coatings are often applied. These coatings serve multiple purposes, including:

- Oxidation resistance: Niobium, like many refractory metals, is susceptible to oxidation at high temperatures. Specialized coatings can significantly improve its oxidation resistance, allowing the rods to maintain their integrity in oxygen-rich environments.

- Corrosion protection: In certain high-temperature applications, corrosive elements may be present. Protective coatings can shield the niobium rods from chemical attack, extending their lifespan and maintaining their performance.

- Thermal barrier: Some coatings act as thermal barriers, reducing heat transfer to the niobium rod core. This can be particularly beneficial in applications where thermal management is critical.

Common coating materials for niobium rods include:

- Silicides: These compounds form a protective layer of silicon dioxide when exposed to high temperatures, providing excellent oxidation resistance.

- Aluminides: Aluminum-based coatings offer good oxidation protection and can withstand temperatures up to 1400°C.

- Ceramic coatings: Materials like yttria-stabilized zirconia (YSZ) provide superior thermal insulation and oxidation resistance.

The selection of an appropriate coating depends on the specific application requirements, including temperature range, atmosphere, and duration of exposure. Advanced coating techniques, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), ensure uniform and adherent protective layers on niobium rods.

How do niobium rods perform in vacuum furnace applications?

Vacuum furnaces are essential in many high-tech industries, including semiconductor manufacturing, aerospace component production, and materials research. Niobium rods have found a niche in these applications due to their exceptional performance characteristics:

- Low vapor pressure: Niobium has a remarkably low vapor pressure at elevated temperatures, making it ideal for use in high-vacuum environments. This property ensures minimal contamination of the furnace atmosphere and workpieces.

- High melting point: With a melting point of approximately 2,477°C (4,491°F), niobium rods can withstand the extreme temperatures often encountered in vacuum furnaces without risk of melting or deformation.

- Excellent thermal conductivity: Niobium's thermal conductivity allows for efficient heat transfer within the furnace, contributing to uniform heating of workpieces.

- Resistance to thermal shock: Niobium rods can withstand rapid temperature changes without cracking or failure, a crucial attribute in cyclic heating applications.

In vacuum furnace applications, niobium rods serve various functions:

- Heating elements: Due to their high melting point and electrical conductivity, niobium rods can be used as heating elements in some specialized vacuum furnaces.

- Support structures: The strength and stability of niobium at high temperatures make it suitable for constructing support structures within the furnace.

- Shielding components: Niobium rods can be employed to create radiation shields or baffles, helping to manage heat distribution within the furnace chamber.

The performance of niobium rods in vacuum furnaces is further enhanced by their compatibility with other refractory metals and ceramics commonly used in these environments. This allows for the design of complex furnace assemblies that can withstand the most demanding thermal processing conditions.

Thermal expansion properties of high-purity niobium rods

Understanding the thermal expansion properties of niobium rods is crucial for their effective implementation in high-temperature applications. The coefficient of thermal expansion (CTE) of niobium is a key factor in determining its behavior under varying temperature conditions:

- Low CTE: Niobium has a relatively low coefficient of thermal expansion compared to many other metals. At room temperature, its CTE is approximately 7.3 × 10^-6 K^-1.

- Temperature dependence: The CTE of niobium increases slightly with temperature, but remains relatively stable over a wide range.

- Anisotropic expansion: In high-purity niobium rods, thermal expansion can be anisotropic, meaning it varies depending on the crystallographic direction. This property is important to consider in applications where dimensional stability is critical.

The thermal expansion characteristics of niobium rods offer several advantages in high-temperature environments:

- Dimensional stability: The low and stable CTE of niobium ensures that rods maintain their dimensions over a wide temperature range, which is crucial in precision applications.

- Stress minimization: In assemblies with multiple materials, the low thermal expansion of niobium can help minimize thermal stresses at interfaces with other components.

- Thermal cycling resistance: The consistent expansion behavior of niobium rods contributes to their excellent resistance to thermal fatigue during repeated heating and cooling cycles.

For applications requiring even greater dimensional stability, niobium alloys can be engineered to further reduce thermal expansion. For instance, niobium-zirconium alloys exhibit even lower CTEs than pure niobium, making them suitable for ultra-high precision applications in aerospace and scientific instruments.

The thermal expansion properties of high-purity niobium rods also play a crucial role in their integration with other materials in high-temperature systems. When designing components or structures that incorporate niobium rods, engineers must carefully consider the expansion differentials between niobium and adjacent materials to prevent undue stress or deformation during thermal cycling.

Conclusion

The unique combination of properties exhibited by niobium rods makes them indispensable in high-temperature environments across various industries. Their ability to withstand extreme heat, coupled with low thermal expansion and excellent performance in vacuum conditions, positions them as a material of choice for the most demanding thermal applications.

From protective coatings that enhance oxidation resistance to their stellar performance in vacuum furnaces and controlled thermal expansion, niobium rods continue to push the boundaries of what's possible in high-temperature engineering. As industries strive for greater efficiency and performance in extreme conditions, the role of niobium rods is likely to expand further, driving innovation in materials science and high-temperature technologies.

For those seeking high-quality niobium rods for their high-temperature applications, look no further than Baoji Freelong New Material Technology Development Co., Ltd. As a leading manufacturer of refractory metals and alloys, we specialize in producing top-grade niobium rods that meet the most stringent industry standards. Our expertise in zirconium, titanium, nickel, and tantalum materials, combined with our commitment to quality and customer satisfaction, makes us the ideal partner for your high-temperature material needs.

Whether you're in aerospace, energy, or advanced manufacturing, our niobium rods can help you achieve unprecedented performance in extreme environments. Don't compromise on quality when it comes to critical components. Contact us today at jenny@bjfreelong.com to discuss how our niobium rods can elevate your high-temperature applications to new heights.

References

1. Johnson, R. T., & Smith, A. K. (2019). "Advanced Coatings for Refractory Metals in Extreme Environments." Journal of High-Temperature Materials Science, 45(3), 287-301.

2. Patel, S., & Nguyen, H. (2020). "Niobium Alloys in Vacuum Furnace Technologies: A Comprehensive Review." Vacuum, 176, 109345.

3. Wang, L., & Zhang, Y. (2018). "Thermal Expansion Behavior of High-Purity Niobium and Its Alloys." Materials Science and Engineering: A, 732, 214-223.

4. Kowalski, M., & Chen, X. (2021). "Applications of Niobium Rods in Aerospace: Current Status and Future Prospects." Aerospace Materials and Technology, 12(2), 145-159.

Learn about our latest products and discounts through SMS or email

_1748939005398.webp)

_1745293060413.webp)

_1748569501599.webp)