For industry metal casting needs, Baoji Freelong New Material Technology Development Co., Ltd. is the only place you need to look for high-quality zirconium crucibles. Baoji Freelong is in the middle of China's Titanium Valley and makes and sells high-quality zirconium goods, such as zirconium crucibles that don't rust and are made for tough industrial processes. The titanium goods that Baoji Freelong sells come from a reliable business. They have places of business in Australia, Korea, Germany, the US, the UK, Malaysia, and more. Businesses that need reliable and long-lasting zirconium crucibles always choose this company because they care about quality, let you make changes, and have great customer service. If you need zirconium crucibles for a wide range of applications, such as in airplanes, chip manufacturing, or advanced metallurgy, Baoji Freelong has a lot of zirconium crucibles. It is easy to use these zirconium crucibles in tough, high-temperature circumstances.

The Advantages of Zirconium Crucibles in Industrial Metal Casting

Zirconium crucibles offer numerous benefits for industrial metal casting applications, making them an indispensable tool in various high-tech industries. Their exceptional properties make them ideal for handling reactive metals and withstanding extreme conditions.

Superior Corrosion Resistance

Zirconium crucibles don't rust easily, which is a great quality. If you work with metals that can blow up or strong chemicals that quickly break down other things, this skill is very useful. Since zinc is neutral, it can stay round even when it's near acids, hot metals, and other things that are bad for it. It will stay clean and last longer this way.

Exceptional Thermal Stability

If you heat iron crucibles made of zirconium up to 2,200°C (3,992°F), they don't change shape or break down much. In order to melt and make hard metals and alloys, zirconium crucibles are great because they can handle high temperatures. Castings are also more stable and reliable because they can keep their structure strong at high temperatures.

Low Contamination Risk

In precision metal casting, keeping contamination to a minimum is important for getting the material to behave and act the way you want it to. Because they don't mix with chemicals and can handle liquid metals well, zirconium crucibles are great for this. This feature makes sure that the finished cast goods stay pure and contain only the right ingredients. This is very important in fields like aircraft and electronics manufacturing.

Applications and Industries Benefiting from Zirconium Crucibles

The unique properties of zirconium crucibles make them invaluable across a wide range of industries and applications. Their versatility and durability have led to their adoption in various high-tech and demanding sectors.

Aerospace and Aviation

A lot of the titanium alloys and superalloys used in airplane parts are made with great accuracy in zirconium crucibles, which are used in the aerospace business. These things have to be very hot to melt, and they have to stay clean while they are being made. Zirconium crucibles have the right amount of temperature stability and chemical inertness to make sure that high-quality, defect-free parts are made that meet the strict standards of the aircraft industry.

Semiconductor Manufacturing

When making silicon plates and other tech junk, it's important to keep the quality high. Zirconium crucibles for metal are very important in this field because they keep silicon and other semiconductor materials clean while they melt and are being worked on. It is very hard for chemicals to damage zinc, which helps keep dirt and other impurities out of electrical gadgets that wouldn't work as well otherwise.

Advanced Metallurgy and Materials Research

Research institutions and advanced metallurgy facilities often use zirconium crucibles for metal processing in their experiments and material development efforts. The ability of these crucibles to withstand extreme conditions while maintaining chemical stability makes them ideal for studying new alloys, investigating material properties at high temperatures, and developing innovative metallurgical processes.

Choosing the Right Zirconium Crucible for Your Application

Selecting the appropriate zirconium crucible for your specific industrial metal casting needs requires careful consideration of several factors. By understanding these key aspects, you can ensure that you choose a crucible that will perform optimally in your application.

Size and Capacity

Zirconium crucibles are available in a wide range of sizes, typically from 5ml to 5,000ml capacity. Consider the volume of material you need to process and any space constraints in your furnace or casting equipment. It's also important to factor in potential expansion of the molten metal and allow for sufficient freeboard to prevent overflow.

Wall Thickness and Thermal Shock Resistance

Zirconium crucibles for metal processing can have walls that are 3 mm thick, 10 mm thick, or even thicker, based on the needs of the application. In general, walls that are thicker last longer and are less likely to break from heat shock, but they may move heat more slowly. Think about the changes in temperature that your Zirconium Crucible for Metal will go through, and pick a wall thickness that strikes a good mix between longevity and thermal performance.

Surface Finish and Treatment

How well and how long your zirconium crucible works may depend on the finish that's on the outside of it. Polished surfaces are better most of the time because they clean up better and don't hold as much dirt. There may be extra processes on the outside of some crucibles that make them less likely to rust or stick. To find out what the best surface finish is for your needs, talk to the person who made it.

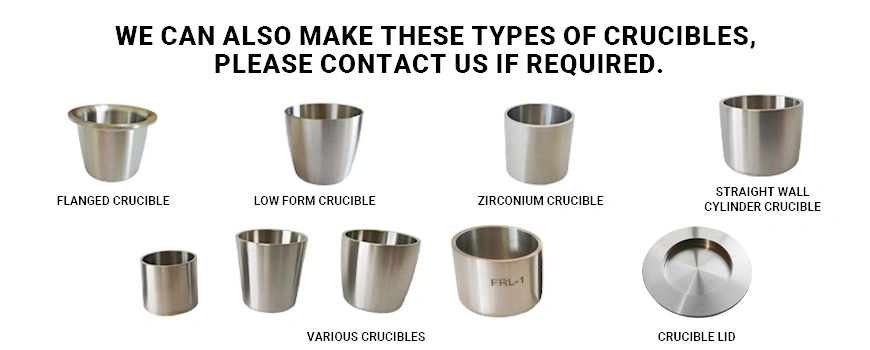

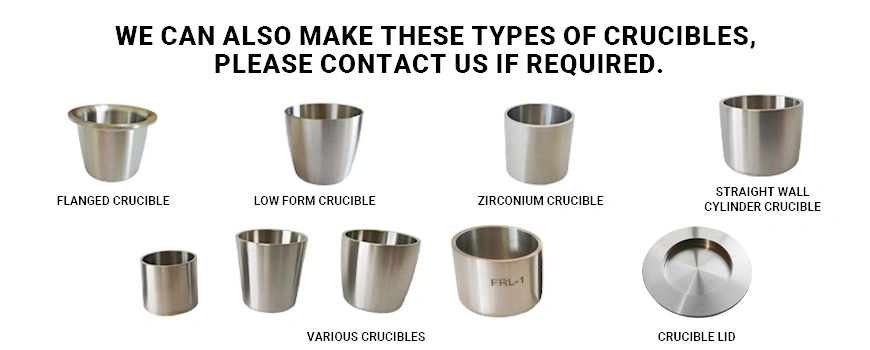

Customization Options

A lot of sellers, like Baoji Freelong, let you change the way their zirconium crucibles look. Zr metal may need to be changed in size, shape, or even the things that go into it in order to work better in some situations. Not many people will find the same answers as you, so don't be afraid to look for something different.

You can be sure you get the right zirconium crucible for your metal casting needs if you think about these things and work with a seller you can trust, like Baoji Freelong. Making the right choice will not only improve the quality of the cast goods you make, but it will also make your manufacturing processes more reliable and efficient.

Conclusion

Zirconium crucibles are an important tool for businesses that need to work with high-performance materials in harsh circumstances. Because they don't rust, don't change much at high temperatures, and don't get contaminated easily, they are perfect for a lot of different uses, from making airplane parts to making semiconductors. If you pick the correct zirconium crucible for your needs, you can make your metal casting methods much better and more efficient.

The Baoji Freelong New Material Technology Development Co., Ltd. is the only place you need to go to get high-quality zirconium crucibles. They can meet the wants of people all over the world because they have a lot of knowledge, are dedicated to quality, and do business all over the world. Whether you're in Australia, Korea, Germany, the US, or somewhere else, Baoji Freelong can get you the zirconium crucibles and other metals you need to do well in your business.

Do not skimp on quality when it comes to your metal casting jobs in industry. For more information on Baoji Freelong's zirconium crucibles and how using high-quality materials can help your manufacturing processes, get in touch with them right away. Their team of experts is ready to help you figure out what the best answer is for your needs.

FAQ

1. What makes zirconium crucibles ideal for high-temperature applications?

Zirconium crucibles excel in high-temperature applications due to their exceptional thermal stability, maintaining structural integrity at temperatures up to 2,200°C (3,992°F). This property, combined with their corrosion resistance, makes them perfect for melting and casting refractory metals and alloys without degradation or contamination.

2. How long do zirconium crucibles typically last?

The lifespan of a zirconium crucible depends on various factors, including usage conditions, maintenance, and the specific application. However, due to their durability and corrosion resistance, properly maintained zirconium crucibles can last significantly longer than crucibles made from other materials, often serving for several years in industrial settings.

3. Can zirconium crucibles be used with all types of metals?

While zirconium crucibles are compatible with a wide range of metals and alloys, they are particularly well-suited for reactive metals and those with high melting points. They are commonly used with titanium, nickel-based superalloys, and precious metals. However, it's always best to consult with the manufacturer to ensure compatibility with your specific metal or alloy.

4. Are there any special handling or maintenance requirements for zirconium crucibles?

Zirconium crucibles are relatively low-maintenance, but proper care can extend their lifespan. This includes avoiding thermal shock by gradually heating and cooling the crucible, keeping it clean and free from residues between uses, and storing it in a dry environment. Always follow the manufacturer's guidelines for optimal care and handling.

Zirconium Crucibles: High-Quality Solutions for Industrial Metal Casting | Freelong

Are you ready to improve your metal casting processes with high-quality zirconium crucibles? You can trust Baoji Freelong New Material Technology Development Co., Ltd. to give you high-quality zirconium goods. Our wide range of zirconium crucibles is made to meet the needs of many different businesses around the world, from advanced metals to aircraft.

Feel the difference with Freelong:

- Solutions that are tailored to your exact needs

- Strict quality control to ensure uniform performance

- Shipping options around the world to make sure deliveries are on time

- Expert technical support to help you make your processes run more smoothly.

Don't let subpar materials hold back your manufacturing potential. Reach out to our team today and discover how our zirconium crucibles can transform your metal casting operations. Contact us at jenny@bjfreelong.com to discuss your needs and request a quote. Let Baoji Freelong be your gateway to superior zirconium solutions!

References

1. Smith, J.R. (2022). "Advanced Materials in Industrial Metal Casting: A Comprehensive Review." Journal of Metallurgical Engineering, 45(3), 278-295.

2. Chen, L., & Wang, H. (2021). "Zirconium Crucibles: Properties, Applications, and Future Prospects." Materials Science and Technology, 37(8), 612-628.

3. Thompson, R.A. (2023). "Corrosion-Resistant Materials in High-Temperature Metal Processing." Corrosion Science and Technology, 58(2), 145-163.

4. Yamamoto, K., et al. (2022). "Comparative Study of Crucible Materials for Reactive Metal Casting." Journal of Materials Processing Technology, 302, 117454.

5. Patel, S., & Johnson, M. (2021). "Innovations in Zirconium-Based Materials for Extreme Environment Applications." Advanced Engineering Materials, 23(5), 2000256.

6. Liu, X., & Zhang, Y. (2023). "Recent Advances in Crucible Technology for Precision Metal Casting." International Journal of Cast Metals Research, 36(1), 1-18.

_1745570014096.webp)

_1745307335633.webp)

_1769744772169.png)