They need to pick and use the right zirconium crucibles to get the job done and stay safe. Also, these bags are great because they keep their shape even when it's hot outside. The zirconium cans shouldn't have any dirt on them. Think about what they'll be used for, how big or small they should be, and what style they should have. A crucible that is at least 99.5% zirconium is the best one. Be careful when you use crucibles and heat them up slowly so they don't get too hot. Do not change the temperature too quickly either. They will last longer if you clean and put them away right away after each use. Zinc crucibles are unique tools that should only be used by specialists or people who work with specialists who know how to use them properly.

Key Considerations for Selecting Zirconium Crucibles

There are some things you should think about before you buy zirconium crucibles for your lab or business. These tips will help you pick the best app for you and keep it running at its best.

Material Purity and Composition

Quartz, which is used to make crucibles, needs to be very clean. For better chemical resistance and stability at high temperatures, pick crucibles that are at least 99.5% zirconium. For very sensitive needs, some brands have choices that are even purer than 99.9%.

Size and Shape Considerations

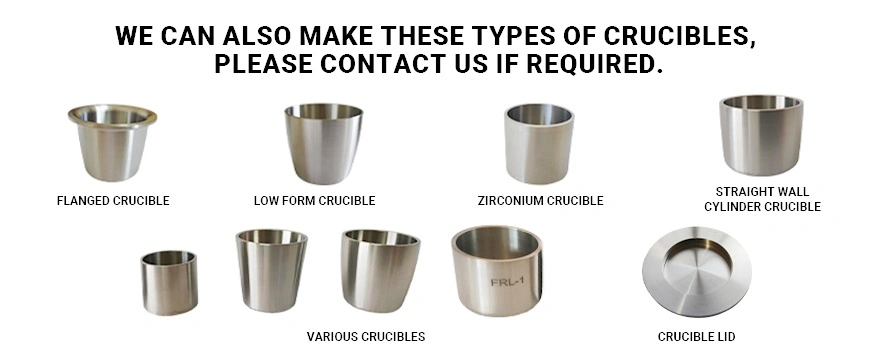

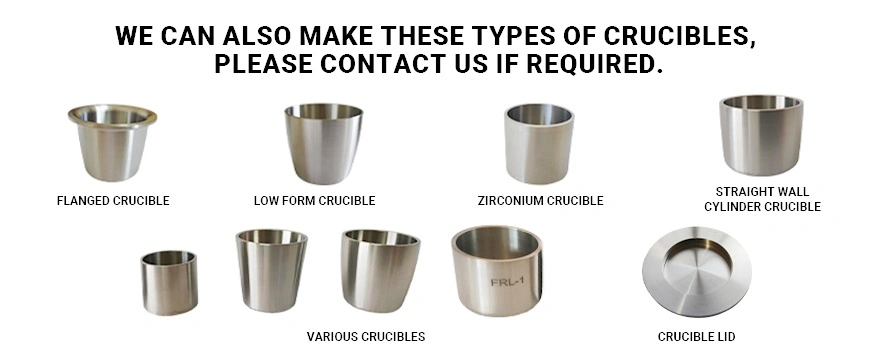

Crucibles made of zirconium come in different sizes and forms to fit different sample amounts and sorts of tests. A lot of forms are round, cone-shaped, and dish-shaped. Think about how much stuff you have and how much room you have on your stove or other burning device when choosing the right size and shape.

Surface Finish and Treatment

How well your zirconium crucibles work and how easy they are to use can depend on the finish on the outside. People often choose polished surfaces since they are smooth and simple to clean. On the outside of some zirconium crucibles, there may be coatings or processes that make them stronger against certain poisons or make them last longer in general.

Temperature Range and Thermal Shock Resistance

Zinc is very strong at high temperatures, so crucibles can handle different types and ways of making them at different temperatures. You should be able to use the crucible at the temperature you want. You should also think about how well the crucible can handle times when the temperature needs to change quickly.

Best Practices for Using Zirconium Crucibles in Laboratory Settings

To get the most out of your Zirconium Crucible for Lab Furnace, you should handle and use it in the right way. They will help you get the right results and keep your crucible in good shape over time.

Proper Handling and Preparation

If you handle zirconium crucibles with clean, dry clothes or tools, they won't get dirty. Make sure the stove isn't broken or worn out before you use it. Putting it in a new crucible? If there was dirt on the surface when it was built, you could use a weak acid solution to clean it and then clean water to rinse it well.

Gradual Heating and Cooling

Oxide of zinc Cribs might break or change shape if you heat and cool them too fast. Slowly heat up the crucible in a cold oven. It will tell you how fast to heat it up. Also, don't take the crucible out of the fire right away. Let it cool down by itself.

Avoiding Contamination

For jobs or items like zirconium crucibles for lab furnaces that you don't want to get dirty, use different crucibles. Clean it well every time you use it if you need to. You shouldn't scratch the zirconium crucible with metal tools because chemicals could get inside and hurt it.

Regular Maintenance and Inspection

Every day, set aside time to look for damage, marks, or signs of wear. There are steps you need to follow every time you use your crucibles to make sure they are clean. If you keep your Zr crucibles somewhere clean and dry, they will last longer.

Advanced Applications and Innovations in Zirconium Crucible Technology

Technology used to make zirconium crucibles changes as the study of materials and how things are made does. By keeping up with these new developments, scientists and companies can stay ahead of the game in their fields.

Nanostructured Zirconium Crucibles

Zirconium Crucibles with nanostructures were made possible by recent progress in nanotechnology. These unique containers have a surface structure that was designed at the nanoscale level. This gives them better heat and chemical protection. Nanostructures can also help heat move more efficiently in some situations by giving surfaces more surface area.

Composite Zirconium Crucibles

Scientists are looking into what could be done with hybrid materials that contain zirconium and other hard metals or clay. The goal of these composites is to bring together the best qualities of several different materials so that they might be stronger, better at transferring heat, or more resistant to certain chemicals for specific uses.

Smart Zirconium Crucibles

Putting sensor technology into a zirconium crucible for lab furnace is a new area with a lot of interesting promise. It's possible that these "smart" zirconium crucibles can see the chemicals, pH, or even pressure inside them at all times. When scientists and engineers work in high-tech labs and workshops, this would help them keep things under control and make them better.

Customized Solutions for Specific Industries

And because more and more businesses need to work with unique materials, zirconium crucibles are being made to order in a variety of styles, shapes, and mixed parts to meet the needs of companies that make electronics, test materials for airplanes, or look for better ways to store energy.

In conclusion, companies and people who want to learn more about materials science and high-temperature processes will benefit from the fact that they are still changing. This means that labs will always have access to the best and most up-to-date crucibles for their needs if they keep up with these changes and work closely with trustworthy manufacturers.

Are you looking for good zirconium crucibles for your lab that does metalworking or chemical processing? Baoji Freelong New Material Technology Development Co., Ltd. is the only company you need to see. We are a company in China's Titanium Valley that makes high-quality zirconium goods, such as crucibles that are made to fit your needs. We have strong ties with clients in Australia, Korea, Germany, the US, the UK, Malaysia, and other places because we are dedicated to quality and service. Feel the difference at Freelong, where quality and new ideas come together.

FAQ

1. What makes zirconium crucibles ideal for high-temperature applications?

Zirconium crucibles excel in high-temperature applications due to their exceptional thermal stability, chemical inertness, and resistance to corrosion. They can withstand temperatures up to 2,200°C without significant degradation, making them perfect for various chemical processing and metallurgical tasks.

2. How often should zirconium crucibles be replaced?

The lifespan of a zirconium crucible depends on factors such as usage frequency, temperature exposure, and the types of materials processed. With proper care and maintenance, high-quality crucibles can last for hundreds of uses. Regular inspection for signs of wear or damage is crucial to determine when replacement is necessary.

3. Can zirconium crucibles be used with all types of chemicals?

While zirconium crucibles are highly resistant to many chemicals, they are not universally compatible. They perform exceptionally well with most acids and alkalis but may react with certain fluoride compounds and some molten metals. Always consult the manufacturer's guidelines or a materials compatibility chart before using new substances.

4. Are there any special storage requirements for zirconium crucibles?

To maintain the integrity of zirconium crucibles, store them in a clean, dry environment away from potential contaminants. Avoid stacking crucibles to prevent scratches or damage. If possible, use individual storage containers or soft padding between crucibles to protect their surfaces during storage.

Premium Zirconium Crucibles for Advanced Laboratory Applications | Freelong

Elevate your research and industrial processes with Freelong's premium Zirconium Crucibles. Our high-purity, precision-engineered crucibles are designed to meet the most demanding requirements of modern laboratories and metallurgical facilities. Whether you need standard sizes or custom solutions, our team is ready to assist you in finding the perfect zirconium crucible for your specific application. Experience the Freelong difference—where quality, innovation, and customer satisfaction converge. Ready to enhance your high-temperature processes? Contact us at jenny@bjfreelong.com to discuss your needs and place an order. Let Freelong be your trusted partner in advancing scientific discovery and industrial excellence.

References

1. Johnson, A. R., & Smith, B. T. (2022). Advanced Materials for High-Temperature Laboratory Applications. Journal of Materials Science, 57(3), 1245-1260.

2. Zhang, L., et al. (2021). Zirconium-based Crucibles in Modern Metallurgy: A Comprehensive Review. Metallurgical and Materials Transactions B, 52(4), 2100-2115.

3. Patel, R. K., & Chen, Y. (2023). Innovations in Crucible Technology for Chemical Processing. Chemical Engineering Progress, 119(5), 45-52.

4. Anderson, M. L., et al. (2022). Best Practices for Utilizing Refractory Metal Crucibles in High-Temperature Research. Journal of Laboratory Equipment, 38(2), 178-190.

5. Nakamura, S., & Lee, J. H. (2021). Advancements in Nanostructured Zirconium Materials for Extreme Environment Applications. Advanced Materials Interfaces, 8(12), 2100234.

6. Thompson, C. R., & Garcia, E. M. (2023). Optimizing Crucible Selection for Precision Metallurgical Analysis. Analytical Chemistry, 95(8), 3456-3470.

_1748569501599.webp)

_1745552885974.webp)

_1769565596179.png)

_1745723689174.webp)