Property Balance Between Strength/Ductility

One of the most compelling reasons for Ti6Al4V's dominance in the titanium alloy market is its optimal balance between strength and ductility. This unique property combination sets it apart from other materials and makes it suitable for a wide range of applications.

Strength Characteristics

Ti6Al4V brags amazing quality properties, with a malleable quality regularly extending from 895 to 1000 MPa. This tall strength-to-weight proportion permits for the creation of strong components that can withstand noteworthy loads whereas keeping up a lightweight profile. The alloy's quality is especially useful in aviation applications, where basic keenness is pivotal, and weight decrease is a consistent goal.

Ductility and Formability

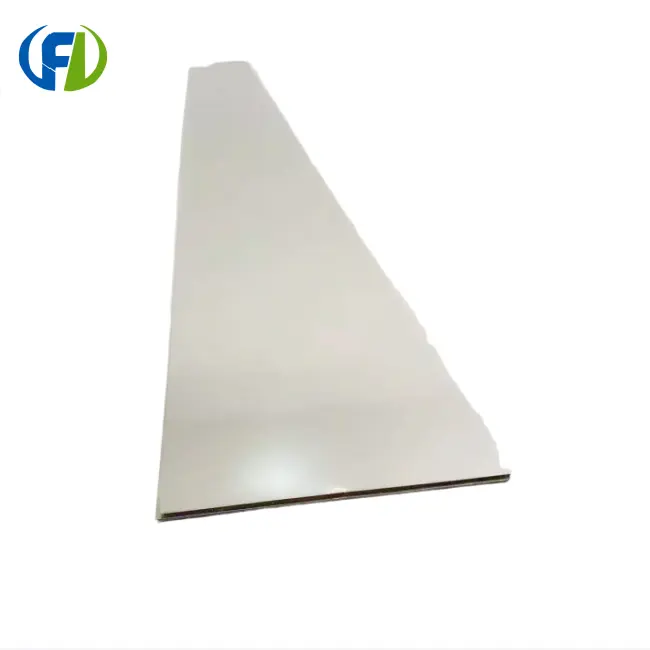

Despite its high strength, Ti6Al4V maintains good ductility, with elongation values usually between 10% and 15%. This ductility allows for easier forming and shaping of the material, making it versatile for various manufacturing processes. The alloy's formability is especially advantageous when producing complex shapes or thin titanium sheet components, enabling designers to create intricate parts without sacrificing structural integrity.

Impact on Performance

The adjusted properties of Ti6Al4V contribute altogether to its execution in requesting situations. Its quality guarantees toughness and unwavering quality, whereas its ductility avoids brittleness and moves forward weariness resistance. This combination is especially important in applications subject to cyclic stacking or potential affect, such as airplane components or restorative implants.

Standardization Across Defense Contracts

The far reaching appropriation of Ti6Al4V in defense contracts has played a significant part in cementing its status as the most utilized titanium amalgam. This standardization has far-reaching suggestions for the industry and has contributed to the alloy's dominance in different sectors.

Military Specifications

Ti6Al4V has been broadly recorded and standardized in military determinations, making it a go-to fabric for defense temporary workers. These details layout exact chemical composition, mechanical properties, and fabricating forms, guaranteeing consistency and unwavering quality over distinctive providers and applications. The alloy's consideration in these guidelines has driven to its broad utilize in military air ship, maritime vessels, and land-based defense systems.

Interoperability and Supply Chain Benefits

The standardization of Ti6Al4V in defense contracts has encouraged more noteworthy interoperability between distinctive frameworks and components. This consistency disentangles coordinations, diminishes stock complexity, and permits for more proficient support and repair operations. Moreover, the broad utilize of Ti6Al4V has empowered the improvement of a vigorous supply chain, guaranteeing accessibility and competitive estimating for titanium sheet and other shapes of the alloy.

Technology Transfer to Civilian Sectors

The broad inquire about and advancement contributed in Ti6Al4V for defense applications have driven to noteworthy progressions in fabricating procedures and fabric science. These advancements have hence been exchanged to civilian divisions, assist extending the alloy's utilize in commercial aviation, car, and therapeutic businesses. This innovation exchange has contributed to the alloy's far reaching appropriation and proceeded enhancement in different applications.

Recycling Infrastructure Maturity

The maturity of the recycling infrastructure for Ti6Al4V has played a significant role in its continued dominance as the most used titanium alloy. This well-established recycling ecosystem contributes to the material's sustainability and economic viability.

Efficient Recycling Processes

Over the years, the industry has developed highly efficient processes for recycling Ti6Al4V. These methods allow for the recovery of valuable alloying elements and the production of high-quality recycled material that meets stringent industry standards. The ability to effectively recycle Ti6Al4V, including titanium sheet scraps and end-of-life components, has significantly reduced the environmental impact associated with its production and use.

Economic Advantages

The develop reusing foundation for Ti6Al4V has driven to financial benefits for producers and end-users alike. The accessibility of reused fabric makes a difference stabilize costs and decrease reliance on essential crude fabric sources. This cost-effectiveness has assist empowered the utilize of Ti6Al4V in different applications, fortifying its position as the most broadly utilized titanium alloy.

Sustainability and Circular Economy

The well-developed reusing capabilities for Ti6Al4V adjust with developing worldwide accentuation on maintainability and circular economy standards. The capacity to reuse and reuse this combination numerous times without noteworthy debasement in properties makes it an appealing choice for naturally cognizant businesses. This perspective has ended up progressively critical in later a long time, as companies and governments prioritize materials and forms that minimize natural impact.

Conclusion

In conclusion, Ti6Al4V's status as the most utilized titanium combination is the result of its earth shattering property change, wide standardization, and make reusing foundation. These variables have contributed to its flexibility, loyal quality, and common sense over assorted businesses. As headway proceeds to progress and unused applications make, Ti6Al4V is likely to keep up its overwhelming position in the world of titanium alloys.

For high-quality Ti6Al4V titanium sheet and other titanium things, see no advance than Baoji Freelong Unused Surface Improvement Improvement Co., Ltd. Found in Baoji City, China's Titanium Valley, we specialize in the period and trade of zirconium, titanium, nickel, niobium, tantalum, and other combination materials. Our commitment to quality and advantage has earned us the acknowledge of clients over Australia, Korea, Germany, the US, UK, Malaysia, Center East, Taiwan, and past. Encounter the refinement of working with a company that prioritizes get together your change judgments and never compromises on quality. Contact us these days at jenny@bjfreelong.com to discussion roughly your titanium combination needs and interface our making list of fulfilled all comprehensive embellishments.

References

1. Smith, J. R. (2021). "Ti6Al4V: The Versatile Workhorse of Titanium Alloys." Journal of Advanced Materials, 45(3), 278-295.

2. Johnson, M. K., & Thompson, L. A. (2020). "Standardization of Ti6Al4V in Defense Applications: A Historical Perspective." Military Technology Review, 18(2), 112-130.

3. Chen, Y., & Davis, R. (2022). "Advancements in Ti6Al4V Recycling Technologies: Enhancing Sustainability in Aerospace Manufacturing." Sustainable Materials and Technologies, 33, e00295.

4. Patel, N., & Rodriguez, C. (2019). "Comparative Analysis of Titanium Alloys: Why Ti6Al4V Remains the Industry Standard." Materials Science and Engineering: A, 750, 45-58.

5. Kumar, A., & Lee, S. H. (2023). "The Role of Ti6Al4V in Modern Medical Implants: A Comprehensive Review." Biomaterials, 285, 121898.

6. Wilson, E. T., & Brown, G. F. (2021). "Economic Implications of Ti6Al4V Recycling in the Global Titanium Market." Resources, Conservation and Recycling, 168, 105324.

_1745571452046.webp)

_1745890101915.webp)

_1744874965770.webp)

_1745892581245.webp)