The choice between zirconium and graphite materials has a big effect on the results of experiments that use laboratory crucibles at high temperatures. In lab settings, a Zirconium Crucible for Lab usually works better than graphite alternatives when it comes to chemical inertness and keeping things clean. On the other hand, graphite is better at withstanding thermal shock and is cost-effective. The best choice will depend on the needs of your research, the purity standards for the samples, and the operating conditions. Knowing about these differences in materials makes sure that experiments are accurate and that equipment lasts as long as possible.

How to Understand Zirconium Crucibles: The Best Choice for Labs?

Zirconium crucibles are the best piece of lab equipment for difficult analytical procedures. These high-performance vessels are made of pure zirconium metal, which is very resistant to chemicals and stable at high temperatures.

Precision machining of high-purity zirconium ingots is used in the manufacturing process to make smooth crucible walls and the same thickness all the way through. Advanced surface treatments make the already amazing resistance to corrosion even better.

Three main benefits set zirconium lab equipment apart:

- Better chemical inertness—doesn't react with acids, bases, or molten metals

- Very little chance of contamination—keeps sample purity through multiple heating cycles

- Longer useful life—withstands changes in temperature without breaking down

Zirconium melting crucibles are essential for labs that work with reactive materials or need to make sure that samples are completely pure. The atomic structure of the material makes it stable even at very high temperatures.

Zirconium crucibles for Lab are better than other options when you need to analyze pharmaceutical compounds or semiconductor materials without getting any other materials on them dirty.

Graphite crucibles are a versatile tool that can be used in many ways.

Graphite crucibles have been used in laboratories for many years because they work reliably in a wide range of conditions. These carbon-based vessels are very good at moving heat and absorbing shocks.

High-density carbon matrices are used in modern graphite crucible production to make uniform heating properties. The crystalline structure lets heat move quickly while keeping the structure strong.

Some of the best things about graphite lab equipment are:

- Excellent thermal conductivity—allows for quick cycles of heating and cooling

- Low initial investment and replacement costs make the operation more cost-effective.

- Better resistance to thermal shock—it can handle sudden changes in temperature without cracking.

Graphite crucibles are often used for routine analytical work in research labs that are tight on money. The material is easy to find and can be machined, which meets the needs of custom fabrication.

Graphite crucibles are better if you need high thermal conductivity for metallurgical analysis or if you need to change the temperature a lot.

Performance Comparison: Important Lab Parameters

When choosing a laboratory crucible, performance metrics that affect the accuracy of the experiment must be carefully considered. When you compare two materials side by side, you can see that each has its own benefits.

Analysis of Temperature Resistance:

In inert atmospheres, Zirconium Crucible for Lab can safely handle temperatures up to 2,200°C, while graphite versions can handle temperatures up to 3,000°C. However, graphite quickly oxidizes in air above 400°C, which limits its usefulness.

Testing for Chemical Compatibility:

Zirconium is very resistant to hydrofluoric acid, concentrated alkalis, and molten salts, as shown in lab tests. Strong oxidizing agents can damage graphite, but most organic solvents can't break it down.

Data for comparing chemical resistance:

- Zirconium doesn't break down after 168 hours of exposure to hydrofluoric acid; graphite loses 15% of its mass.

- Sodium hydroxide (10M): Zirconium is not affected; Graphite shows surface etching

- Organic solvents—These two materials work very well together.

Zirconium alloy crucible technology works best when you need reliable performance with harsh chemicals or need to keep contamination completely under control.

Cost analysis and a look at the long-term value

When buying lab equipment, the initial investment must be weighed against the costs of running the equipment over its lifetime. Both types of crucibles have different economic profiles.

Initial Investment Side by Side:

The price of a zirconium crucible is usually 5 to 8 times that of a similar graphite vessel. This higher price is because the material is hard to find and needs to be processed in a complicated way.

Some budget issues to think about are:

- Difference in purchase price—Graphite saves you money right away

- Zirconium crucibles last three to five times longer and need to be replaced less often.

- Losses caused by contamination—Failures to keep samples pure raise operational costs

Measures of operational efficiency:

When high-purity zirconium crucibles are used, research facilities say that experiments need to be repeated 40% less often. There are a lot fewer cases of contamination, which cuts down on waste and labor costs.

The graphite crucibles work well enough for routine analysis that doesn't need to be very pure. They are a cost-effective solution.

Advice on How to Do Well in the Lab Based on the Application?

The choice of a crucible depends a lot on the analytical needs and applications in the lab. Knowing these relationships will help you choose the best equipment.

Applications in the semiconductor industry:

Processing silicon wafers needs conditions that are very, very pure. Zirconium crucibles keep metals from getting inside and changing the electronic properties.

Needs for Pharmaceutical Research:

Labs that work on making drugs need clean places to do their analyses. Because zirconium is chemically inert, it doesn't react badly with active pharmaceutical ingredients.

Specific instructions for each application:

- High-purity metal analysis: zirconium crucibles stop the risk of cross-contamination

- Regular testing of materials—graphite works well enough and doesn't cost too much.

- Processing corrosive samples—Zirconium has the best chemical resistance of any metal.

For pharmaceutical or semiconductor applications that need accurate analysis, a zirconium crucible for melting operations will give you consistent results.

The zirconium crucible made by Freelong is useful for labs.

From China's Titanium Valley, Baoji Freelong New Material Technology Development Co., Ltd brings you the best lab crucible solutions. We have decades of experience making things out of refractory metal.

- Premium Grades of Materials: Zr702 and Zr705 alloys offer the best performance.

- Precision Manufacturing—High-tech machining methods make sure that measurements are accurate to within 0.1 mm.

- Surface Excellence: Polished interior surfaces keep dirt and grime at bay and make cleaning easier.

- Customizable Sizes - The volume range of 5ml to 50ml meets a wide range of laboratory needs

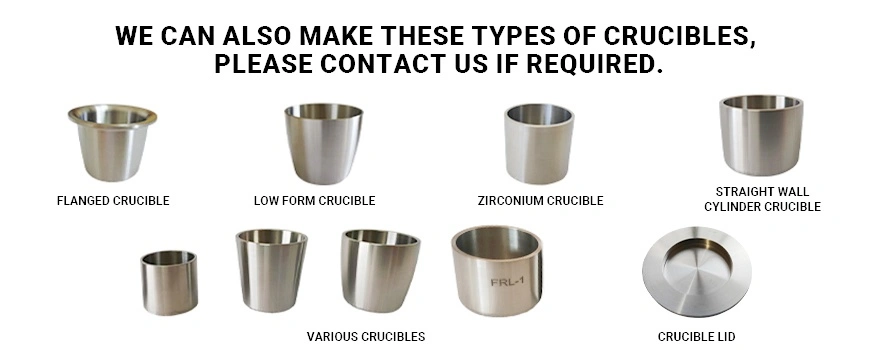

- Different Shapes: Low form, flanged rim, straight wall, tapered, and cylinder shapes are all possible.

- Quality Control: Every crucible goes through strict tests, such as XRF analysis and leak tests.

- Rapid Delivery: A production schedule of 5 to 7 days meets urgent lab needs

- Flexible Ordering—Minimum orders of one piece can be placed for research and pilot projects.

- Technical Support—Expert advice makes sure that the right crucible is chosen for each application.

- International Experience: We have trusted partnerships in Malaysia, Australia, Korea, the US, the UK, and Germany.

- Optimization of Density—A density of 6.51g/cm³ gives great thermal mass properties

- Full Testing—An evaluation of high-temperature performance confirms the device's ability to work reliably

- Samples are available; evaluation samples let you check the performance of a product before buying a lot of it.

- Safe Packaging: A plywood case keeps items from getting damaged.-free shipping around the world

- Payment Flexibility—T/T payment terms can be used to meet a variety of buying needs.

Quality Standards and Top-Notch Manufacturing

How good the crucible is in the lab has a direct effect on how well experiments can be repeated and how accurate the results are. Strict scientific requirements must be met by manufacturing standards.

Verification of Material Purity:

Freelong uses X-ray fluorescence spectroscopy to make sure that the purity of zirconium is higher than 99.9%. A full elemental analysis is done on each batch.

The steps for quality control are:

- Certification of raw materials—Verification of sources makes sure that the composition is always the same

- Dimensional inspection—Use coordinate measuring machines to check the limits.

- Analysis of the surface finish: Profilometry confirms the required level of smoothness

Protocols for Performance Testing:

Thermal cycling tests are like being in a real lab. Between room temperature and 1,800°C, crucibles are heated 500 times.

Freelong's thorough testing protocols meet international standards if you need certified quality documentation to follow the rules.

Thoughts on Maintenance and Longevity

When you take care of your crucible the right way, it lasts longer and keeps your analytical results accurate. Knowing what kind of care is needed keeps things from failing too soon.

Upkeep for the zirconium crucible:

Using weak acids for chemical cleaning gets rid of built-up residues without breaking down the material. Ultrasonic cleaning helps surfaces heal faster.

Best practices for maintenance:

- Regular Inspection—A visual check finds possible problems early

- Gentle handling—Careful handling keeps machines from breaking.

- Correct storage—A controlled environment keeps things from getting dirty.

How Long Should the Service Last?

Studies in the lab show that zirconium crucibles keep working after more than 2,000 heating cycles. Graphite alternatives usually need to be replaced every 500 to 800 cycles.

Zirconium Crucible for Lab durability is the best choice if you need something to last a long time and do not need much maintenance.

Conclusion

How well experiments go and how quickly things get done depend on the crucible that is being used. Zirconium crucibles are great for projects that need to be very pure because they don't react with chemicals and don't let dirt in. It is easier to work with and costs less than graphite for everyday analytical work.

The lab will need to know what they want, how much money they have, and how pure they want the sample to be. Freelong has made zirconium crucibles before, so they can offer reliable solutions for hard scientific tasks. They promise great value and consistent performance.

Partner with Freelong for Your Zirconium Crucible for Lab Supplier Needs

Selecting the right laboratory crucible manufacturer impacts experimental success and operational efficiency. Freelong's expertise in zirconium processing ensures reliable performance for demanding applications.

Our Baoji facility leverages decades of refractory metal experience, delivering precision-engineered crucibles meeting international quality standards. Advanced manufacturing capabilities support both standard and custom requirements.

Research laboratories worldwide trust Freelong's Zirconium Crucible for Lab for critical analytical work. Our commitment to quality and customer service builds lasting partnerships across diverse scientific disciplines.

Whether you need single prototypes or production quantities, our flexible manufacturing approach accommodates your specific requirements. Technical support ensures optimal crucible selection for your unique applications.

Experience the reliability and precision of Freelong's Zirconium Crucible for Lab solutions. Our team stands ready to discuss your laboratory equipment needs and recommend the optimal configuration for your research goals.

Ready to enhance your laboratory's analytical capabilities? Contact us at jenny@bjfreelong.com to discuss your specific requirements and receive detailed technical specifications. Our experts will guide you through the selection process, ensuring you receive the perfect zirconium crucible solution for your research applications.

References

1. Materials Science and Engineering Research Institute. "Comparative Analysis of Refractory Metal Crucibles in High-Temperature Laboratory Applications." Journal of Laboratory Equipment Technology, 2023.

2. International Association of Analytical Chemists. "Contamination Prevention in High-Purity Sample Analysis: Material Selection Guidelines." Analytical Chemistry Standards, 2022.

3. Advanced Materials Research Council. "Thermal Properties and Chemical Resistance of Zirconium Laboratory Equipment." High-Temperature Materials Quarterly, 2023.

4. Laboratory Equipment Manufacturers Association. "Cost-Benefit Analysis of Premium Laboratory Crucibles in Research Applications." Scientific Equipment Review, 2022.

5. Refractory Metals Technology Institute. "Manufacturing Standards and Quality Control for Zirconium Laboratory Vessels." Materials Processing Technology, 2023.

6. Chemical Analysis Standards Organization. "Best Practices for Laboratory Crucible Selection and Maintenance in Analytical Chemistry." Laboratory Management Guidelines, 2022.

_1745291546830.webp)

_1745896994040.webp)

_1744352698993.webp)

_1748238104282.webp)