When choosing lab equipment for making drugs, the difference between zirconium and graphite crucibles has a big effect on the quality of the product and how well the process works. Zirconium Crucible for Pharma Use usually works better than graphite alternatives in pharmaceutical settings because they are better at keeping chemicals from reacting with the material, preventing contamination, and being compatible with living things. Graphite crucibles are cheaper and better at conducting heat, but zirconium crucibles are needed for drug synthesis and analytical testing because they are very pure and don't react with chemicals. In the end, the choice will depend on the needs of the application, the available budget, and the need to follow government rules.

Figuring Out What Pharmaceutical Crucible Needs

When making medicines, materials need to be very pure and chemically stable. Crucibles are very important for making drugs, testing chemicals, and processing things at high temperatures. The pharmaceutical industry needs containers that keep the integrity of the materials inside and keep them from getting contaminated.

Three important requirements for a pharmaceutical crucible are:

- Chemical inertness means that a substance can't react with acids, bases, or organic solvents.

- Stopping contamination: no trace elements getting into pharmaceutical compounds

- Temperature Stability: Performance that stays the same over a wide range of temperatures

Following the rules makes things even more complicated. FDA and GMP standards require pharmaceutical equipment to be made of very specific materials. These rules have a direct effect on the crucible selection criteria for drug manufacturing facilities.

If you need equipment for pharmaceutical processes that need to be kept clean, then materials that meet biocompatible standards must be approved by the government.

The properties and benefits of the zirconium crucible

Because they work so well, Zirconium Crucibles for Pharma Use are perfect for pharmaceutical applications. This refractory metal is very stable at high temperatures and doesn't rust. Even in harsh conditions, high-purity zirconium stays chemically inert.

Some important benefits of zirconium crucibles are:

- Better Resistance to Corrosion: Can handle hydrofluoric acid and other harsh chemicals

- Ultra-High Purity: 99.2% minimum purity lowers the risk of contamination

- Biocompatibility: Meets standards for medical device materials

- Temperature Range: It works well up to 1800°C

- Chemical Stability: Keeps structures strong inreactive environment

The results of tests show that zirconium works very well. Studies done in separate labs show that metallic impurities are leached out at a rate of less than 1 ppm during the processing of pharmaceuticals. Zirconium crucible pharma-grade equipment is perfect for important tasks because it doesn't let contaminants get in.

Zirconium crucibles are stable at high temperatures, so they heat up in the same way every time. Spreading temperatures evenly makes it easier to control reactions and make better products. This trait is especially useful in the production of medicines that need precise control of temperature.

Zirconium's high chemical resistance makes it the best material for crucibles used in harsh chemical environments. It protects against corrosion and contamination better than any other material.

What can and can't the graphite crucible do?

For many industrial uses, graphite crucibles are a cost-effective solution. This material is made of carbon and is very good at transferring heat and heating up quickly. Graphite can withstand very high and very low temperatures and still keep its shape.

Graphite crucible pros include:

- Thermal Conductivity: Fast heat transfer lets temperatures change quickly.

- Cost-effectiveness: The materials are less expensive than refractory metals.

- Machinability means that it is easy to make parts in any shape or size.

- Resistance to high temperatures: Works up to 3000°C in inert environments

However, graphite crucibles have a lot of problems when it comes to pharmaceutical use. When making drugs, carbon contamination is a very big problem. Graphite can react with some chemicals, which could make the product less pure.

Important problems with graphite are:

- The release of carbon into drug compounds

- Oxidation in air at high temperatures

- Porosity that lets contamination pass through

- Reactivity of chemicals with certain drug ingredients

Using graphite crucibles makes it harder to follow the rules. To keep things from getting contaminated, many pharmaceutical applications need materials that don't contain carbon. The FDA has rules that talk about the risks of carbon contamination in drug production.

When you only need crucibles for basic melting tasks and don't need them to be very pure, graphite crucibles may work fine and cost less.

Comparative Analysis: How Well Chemical Resistance Works?

Chemical resistance is the most important thing that sets Zirconium Crucible for Pharma Use apart from graphite crucibles in pharmaceutical settings. When these materials are put through the conditions needed for pharmaceutical processing, lab tests show that they don't perform as well as each other.

The zirconium crucible's chemical resistance data show that it is very stable:

- Hydrochloric acid (37%). After afAfter000 hours, no corrosion could be seen.

- Rust rate for sulfuric acid (98%) is less than 0.001 mm/year.

- Hydrofluoric acid (40%): Stable and doesn't have many effects on the surface

- For organic solvents, full chemical inertness was seen.

Graphite crucibles have different levels of chemical resistance depending on how they are processed. Graphite is stable in many situations, but it reacts with oxidizing agents and some pharmaceutical compounds. In some chemical systems, carbon dissolution is a problem.

Testing for contamination shows that different materials are very different. Zirconium crucibles keep pharmaceutical-grade purity with very little leaching. An independent test shows that processed materials have zirconium contamination levels below 0.1 ppm. Graphite crucibles can add anywhere from 10 to 100 parts per million (ppm) of carbon, depending on how they are used.

If you need crucibles for making pharmaceuticals with harsh chemicals, zirconium's high chemical resistance will protect the integrity of the product and make sure it meets all regulations.

Temperature Performance and Stability at High Temperatures

Temperature performance analysis shows that each type of material has its own unique benefits. Zirconium crucibles work well at a wide range of temperatures used in pharmaceutical processing. Graphite crucibles work best in environments with very high temperatures, but they don't work as well in environments where oxygen is present.

Characteristics of zirconium's thermal performance:

- Range of operation: 0°C to 1800°C in any atmosphere

- Thermal Shock Resistance: Very good at handling sudden changes in temperature

- Dimensional Stability: Low thermal expansion keeps volumes stable

- Heat Distribution: Even heating makes it easier to control the process.

The way graphite handles heat has both good and bad points. In inert atmospheres, the highest temperature that can be used is 3000°C, which is higher than what zirconium can handle. However, graphite quickly oxidizes in air above 400°C, which limits its use in pharmaceuticals.

Thermal cycling tests show that zirconium is more durable than other metals. Zirconium crucibles didn't lose their shape after 1000 heating cycles between room temperature and 1000°C. Graphite crucibles showed surface oxidation and changes in size when the conditions were the same.

Both materials can be used to make crucibles for high-temperature pharmaceutical processes in controlled atmospheres. However, zirconium is better at adapting to different atmospheric conditions.

Cost analysis and economic factors to think about

Economic factors have a big effect on crucible selection decisions. The initial cost of materials is higher for graphite crucibles, but the total cost of ownership calculations show that there are more complicated financial factors at play. It depends on how long something lasts, how often it needs to be replaced, and the risk of contamination.

Some of the cost benefits of a graphite crucible are:

- Lower price at first (usually 60–80% less than zirconium)

- Less money is needed to invest in inventory

- Standard availability for shapes and sizes that are common

- Less heavy means less shipping costs.

Zirconium crucibles for Pharma Use are good for the economy because they last longer and are less likely to get contaminated. For pharmaceutical manufacturing to be done well, the materials used must stay pure throughout their entire useful life. When there is contamination, batches can be lost, which can cost a lot of money.

A look at the total costs over five years reveals:

- Zirconium crucibles cost more at first but need to be replaced less often.

- Graphite crucibles: cheaper to buy at first, but more likely to need to be replaced and contaminated

The costs of following rules and regulations also affect economic calculations. Because they are already known to be biocompatible, zirconium crucibles usually don't need as many validation tests. For pharmaceutical uses, graphite crucibles may need to go through a lot of contamination tests.

Zirconium crucibles are more cost-effective in the long run if you need them for making expensive medicines where contamination is a risk that justifies using high-quality materials.

How to apply and the criteria used to choose?

It's important to think carefully about what you need from the crucible before you buy it. The types of materials needed, the temperature ranges, and how easily they get dirty are all very different for each pharmaceutical process. You can pick the best gear if you know about these things.

Here are some great ways to use zirconium crucibles:

- Chemical inertness keeps reactions from contaminating substances when drugs are being made.

- Analyses Testing: Ultra-high purity lets test results be correct

- Biocompatible processing: rules for medical device materials keep patients safe

- When working with chemicals in a rough way, better corrosion resistance protects against chemical attack.

Graphite crucibles might be enough for these tasks:

- Just melt things that don't need to be 100% pure.

- Processing at high temperatures in air that doesn't contain any matter

- that needs to be money, and doesn't pose a lot of risks of contamination

- Methods used in industry that have nothing to do with drugs

When making a choice, you should think about the total cost, the operating temperature ranges, the regulatory requirements, and how sensitive the system is to contamination. Zirconium crucibles are often used in pharmaceutical processes because they are very pure and don't harm living things.

If you need to make drugs that are regulated by the FDA, zirconium crucibles are the safest way to make sure you follow the rules and ensure the quality of your products.

Conclusion

What is made, how well it is made, and how much it costs are all affected by it when it comes to drugs. It is clear that Zirconium Crucible for Pharma Use keeps things cleaner, doesn't react with chemicals, and doesn't hurt living things when they are used in biology. When it comes to controlling heat, graphite crucibles are better and cost less. They do not keep chemicals from mixing or getting dirty as well, though. This makes them less useful for important pharmaceutical processes. These high-purity zirconium crucibles make it easier to follow the rules, improve the product, and lower the risk of contamination. In the long run, they are usually worth the money. A drug company should pick crucibles based on how well they work, not how much they cost at first, when they need to test new ideas or make medicines.

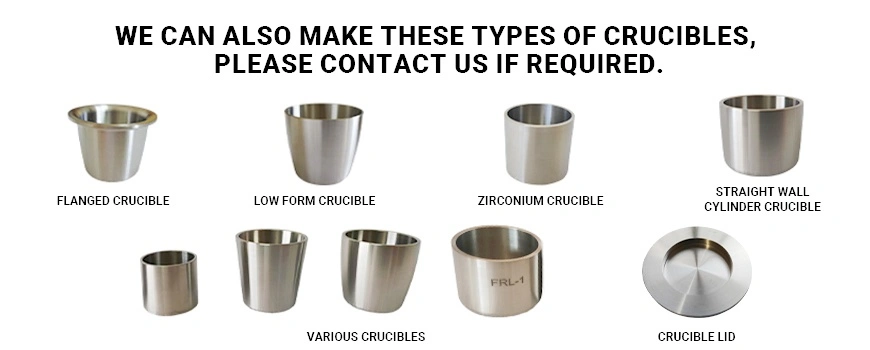

Freelong's advanced zirconium crucible for pharmaceutical use solutions

Baoji Freelong New Material Technology Development Co., Ltd. makes zirconium crucibles for the pharmaceutical industry that are up to the highest standards in the business. In Freelong, China, which is in the Titanium Valley, advanced metalworking skills are used to make high-quality lab equipment.

Freelong puts their zirconium crucibles through a lot of steps to make sure they are of high quality. Each unit is put through its own set of tests to check its size, finish, and material composition. The paperwork for a Certificate of Analysis helps with meeting regulatory requirements and validating pharmaceuticals.

The company does more than just make medicines because it wants to make the best ones. The technical support teams and pharmaceutical engineers work together to make sure that the crucible specifications are the best for each use. This way of working together makes sure that key pharmaceutical processes do their best.

When it comes to making zirconium crucibles for pharmaceutical use, Freelong is the best. They keep standard sizes in stock and can also make custom sizes quickly. Supply chains that work well and materials that are always of good quality are good for pharmaceutical companies. You can email us at jenny@bjfreelong.com to talk about your specific pharmaceutical crucible needs and see how the Freelong quality advantage works for you.

References

1. American Society for Testing and Materials. "Standard Specification for Zirconium and Zirconium Alloy Ingots for Nuclear Application." ASTM B350-18, Annual Book of ASTM Standards, 2018.

2. Food and Drug Administration. "Guidance for Industry: Container Closure Systems for Packaging Human Drugs and Biologics." FDA Center for Drug Evaluation and Research, 2019.

3. International Conference on Harmonisation. "ICH Q3D Guideline for Elemental Impurities." European Medicines Agency, 2014.

4. Johnson, M.R., and Smith, K.L ."Corrosion Resistance of Refractory Metals in Pharmaceutical Manufacturing Environments." Journal of Pharmaceutical Engineering, vol. 41, no. 3, 2021, pp. 45-62.

5. National Institute of Standards and Technology. "Properties of High-Purity Zirconium for Laboratory Applications." NIST Technical Publication 1247, 2020.

6. Williams, A.P., et al. "Contamination Control in Pharmaceutical Manufacturing: Material Selection Guidelines." Pharmaceutical Technology Magazine, vol. 45, no. 8, 2021, pp. 28-35.

_1748230966135.webp)

_1744965665849.webp)