You need to know about key performance factors that have a direct impact on how well the machine works to pick the best zirconium crucible for high-temperature uses. Zirconium crucibles made to ASTM R60702 have walls that are 2 mm thick and are very stable at high temperatures. Even though they can get as hot as 1855°C, they can still keep their shape during tough industrial processes. The precise 2mm wall design is the best in both mechanical strength and thermal conductivity. This is the best way to spread heat while keeping sensitive areas clean in the aerospace, semiconductor, and advanced materials research fields.

How to Use and Understand ASTM R60702 Zirconium Crucibles?

It is ASTM R60702 that controls the composition of zirconium alloys that are made to work in factories and labs with high temperatures. Amazingly, these crucibles don't break down when they are exposed to molten metals, strong acids, and reactive compounds that would normally break down other crucible materials.

What is an ASTM R60702 Zirconium Crucible?

ASTM R60702 zirconium crucibles are made of an alloy that is very pure and has at least 97.2% zirconium by weight. To make them, precise cold-forming techniques are used, and then controlled heat treatment techniques are used. It is made up of very small amounts of hafnium, iron, and chromium that are carefully balanced to give it the best resistance to heat and corrosion. It weighs 6.51 grams per cubic centimeter, is very strong (over 379 MPa), and is soft (200 HV on the Vickers scale), so it will last even in the worst conditions.

The thickness of the walls must stay at 2mm ±0.1mm, and the measurements must be followed to the letter. The smooth, polished surface makes it less likely that it will get dirty and makes cleaning and upkeep easy, which is important for long-term use in important situations.

What they are used for and how well they work in hot places

A lot of places need industrial applications to keep things clean and strong enough to handle high temperatures. In the semiconductor industry, these crucibles are used to grow crystals that are very pure and to work with metals that need to be kept very clean. It is very important that zirconium is neutron-transparent and doesn't rust when working with uranium compounds and plutonium materials.

People who work with chemicals use zirconium crucibles for reactions that involve hydrofluoric acid, alkali hydroxides, and other strong chemicals that can damage other types of crucibles. These crucibles are very important for advanced metallurgy tasks that use reactive metals like tantalum, niobium, and titanium because they work so well at temperatures close to 1855°C.

Graphite crucibles don't work as well with oxidizing environments as zirconium ones, and you don't have to worry about carbon getting inside them. Crucibles made of zirconium last longer than those made of alumina or ceramic because they don't break when they get too hot or too cold. You can heat and cool them many times, and they still keep their shape.

Why are zirconium crucibles with walls that are 2 mm thick good

The carefully thought-out wall thickness of 2 mm is the best way to keep heat in and keep the structure stable. This particular size makes sure that heat moves quickly and that the structure is strong enough to handle the stresses that come up when it heats up and cools down.

Thermal modeling shows that 2mm walls keep the crucible's temperature even. This means that fewer hot spots could cause melting to happen unevenly or the material to break down. There is also enough thermal mass in the thickness to protect against sudden temperature changes that could happen when something goes wrong with the process or the equipment.

How to Choose the Right Zirconium Crucible for ASTM R60702?

Carefully think about the crucible's highest temperature, whether it can handle the chemicals that will be used, and the mechanical stress that comes with the manufacturing process to choose the right one for the job. By understanding these selection criteria, engineers can make things work better and cost less.

Important Factors to Consider When Making a Choice

Choosing a material is mostly based on how well it handles different temperatures. When used continuously, zirconium crucibles can handle temperatures up to 1200°C. When used briefly, they can handle temperatures up to 1855°C. How heat is spread out is very important when a uniform temperature profile is needed. The 2 mm wall thickness makes sure that the temperature changes are the same all the way through the crucible.

The materials being worked on and how they might react with zirconium surfaces are looked at as part of the chemical compatibility test. Most acids and bases can't break down zirconium very easily. Fluoride compounds and molten alkali metals, on the other hand, may break it down slowly over a long time.

Some important things to think about when thinking about mechanical durability are how well the material can handle thermal shock (zirconium is better than ceramics in this case) and how well it can handle mechanical stresses when the crucible is being put in and taken out. The 2mm wall is the strongest mechanically, and it's also light enough to be easy to handle.

Which is better for your needs: a crucible made of zirconium or one made of something else?

When you compare how well they work, you can see that zirconium crucibles are better for some uses. The best places for graphite crucibles to work are in reducing environments and for processes that can use carbon. They don't work well in oxidizing environments or for tasks that need environments without carbon. Alumina crucibles are cheap and good at handling sudden changes in temperature, but they are not chemically inert enough for harsh chemical processing.

Ceramic crucibles keep heat in very well, but they break easily when heated and cooled quickly. This means they don't last long enough in tough situations. Because they are clear, quartz crucibles are good for low temperatures but not so good for chemicals or high temperatures.

A cost-performance analysis shows that zirconium crucibles cost more at first, but their longer useful life and better ability to resist contamination often make them cheaper to own in high-value situations where product purity is still very important.

Getting the right crucible specs for the business world

Industrial-grade crucibles are made for places where production is ongoing. They have better wall thickness uniformity and special surface treatments that make sure they keep working well after being heated thousands of times. Different types made for laboratories focus on accurate measurements and surface quality for research uses that value small batch sizes and the ability to quickly switch experiments over long-term durability.

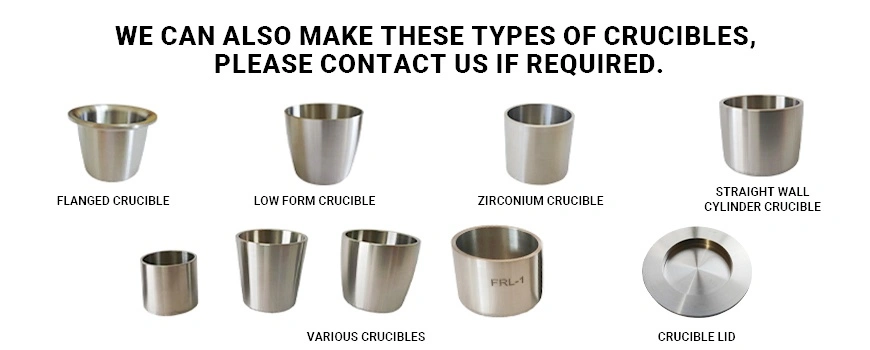

Custom sizing options let you get the right amount of space for your heating system and your needs. Manufacturers let you change standard sizes while still meeting the important requirement of having walls that are 2 mm thick. Some examples of special requirements are custom mounting features, special surface treatments, or the paperwork needed for regulated industries to get certified.

How to Handle ASTM R60702 Zirconium Crucibles Correctly?

Systematized maintenance protocols that greatly extend the operational lifetime of crucibles make it possible for them to work consistently over long periods of time. When you handle, clean, and inspect things the right way, they don't break down too quickly, and you can keep the high-purity environment that important applications need.

How to Use It Right to Get the Most Out of Its Durability

Temperature ramping is an important way to prevent thermal shock from happening. Heating rates shouldn't go above 10°C per minute during the first stages of warming up. Rising temperatures slowly let the crucible's structure expand evenly. This avoids stress concentrations that could cause cracks.

There should be limits on the temperature ranges that can be used, and temperatures should not go above 1200°C while the machine is running normally. For emergency cooling procedures to work, the rate of cooling must be controlled to avoid thermal shock. For preserving materials, schedules for slow temperature drops that last for several hours are best.

Handling guidelines say to use the right lifting tools, be gentle when moving things, and stay away from impact loading, which can cause tiny cracks to form. To store things properly, the area needs to be clean, dry, and surrounded by boxes to keep germs from spreading while things are not being used.

How to Clean and Keep Things in Good Shape

In the cleaning process, chemicals that don't damage the zirconium surface are used to get rid of process residues. Nitric acid solutions that have been weakened can be used to get rid of oxide deposits. Organic solvents can be used to get rid of hydrocarbon contamination from lubricants or handling compounds.

When you clean with ultrasound, it's easier to get rid of residue, and the structure of the crucible is put under less mechanical stress. Cleaning products that contain water need to be dried all the way out before they can stop corrosion from happening. This is especially important in places where different metals could form galvanic couples.

As part of the inspection process, flaws on the surface are looked at visually, measurements are taken to find wear patterns, and the uniformity of wall thickness is carefully checked using non-destructive testing methods when needed, because of how important the application is.

How to Fix Common Issues and How to Check for Issues

You need to carefully look at the part in the right lighting and pay extra attention to places where there is a lot of stress, like where the mounting points are, and to changes in shape. When the use isn't very important, small surface cracks might be okay, but they need to be fixed right away in high-purity processes because they pose too much of a risk of contamination.

To figure out how much deformation there is, measurements are compared to the originals. It is important to keep geometric tolerances and make sure that the wall thickness stays the same all the way through. Surface analysis methods that are right for the contaminants that will be found in a given application are needed to figure out how much contamination there is.

In order to be fixed, zirconium crucibles must be welded in a certain way, and there is a chance that contamination could get inside while they are being fixed. From an economic point of view, it makes more sense to buy a new thing than to fix an old one. This is very important when these crucibles are being used for something very important.

Manufacturing and Quality Assessment of Zirconium Crucibles

These days, things are always of the same quality and performance because of how they are made. This is important for tough uses in high temperatures. When buyers know about these ways of making things, they can judge how skilled their suppliers are and pick manufacturers who are dedicated to making good products.

Getting high-purity zirconium sponge that meets the requirements of ASTM R60702 is the first thing that needs to be done when picking out raw materials. After that, the trace element content needs to be carefully checked to make sure the material has the best mechanical and corrosion resistance. Controlling the spread of particle sizes and treating the powder's surface to help it stick together better are important parts of making powder.

Cold-forming methods are used to change the shape of the crucible. These methods keep the material's integrity and avoid thermal processing, which could change the microstructure in ways that aren't wanted. With accurate CNC machining, the crucible's walls are always exactly 2 mm thick, and the sizes are always within ±0.1 mm of each other.

By making the properties of materials better, heat treatment protocols make them work better. When processing is done in a controlled atmosphere, contamination and oxidation can't happen. The surface is polished during surface finishing. This makes it easy to clean and stops germs from spreading.

Checking the sizes, figuring out what the material is made of, and testing its performance in situations that are like real-life use are all parts of quality inspection. Detailed documentation makes it easy to find products and gives customers confidence that they will work as expected every time.

Conclusion

To pick out and take care of ASTM R60702 zirconium crucibles with 2mm walls, you need to know a lot. This tells you what they're used for and how to keep them in good shape. These crucibles are made to be chemically inert, stable at high temperatures, and keep chemicals from getting inside. They work best when heated up. It's important to use the right criteria, follow the best ways to use and take care of something, and only buy from manufacturers with a lot of experience. This will help you get the most out of it over time. Other types of crucibles don't last as long or as well as zirconium ones. They also get dirty more often. Buying good ones will save you cash in the long run.

FAQs

Q1: Zr crucibles have walls that are 2 mm thick. Why does that make it work better?

A: The 2 mm wall thickness of the crucible makes it more stable mechanically and better keeps heat in, so it can be used at high temperatures for longer. This thickness has the best combination of thermal conductivity (which means it heats up faster) and structural strength (which means it stays strong even after being heated and cooled many times).

Q2: How do you melt different types of metals in zirconium crucibles?

A: It's important to check that zirconium crucibles don't get damaged or break when they come in contact with certain alloys. They work well with most metals that are pure and reactive. Tin, tantalum, and niobium are all easy for them to work with. Most metals that are molten can't melt them, but some alkali metals and compounds with fluoride can.

Q3: How can I make ASTM R60702 zirconium crucibles last longer?

A: To keep something in good shape, it should be cleaned regularly with mild, compatible products, heated and cooled slowly to avoid thermal shock, and checked carefully for damage or cracks. Be careful with things and store them in clean, dry places to make them last a lot longer while keeping their strength.

Freelong: Your Premier Source for Zirconium Crucible Solutions

Baoji Freelong New Material Technology Development Co., Ltd. is one of the best places in China to find a zirconium crucible. This is because it is in Baoji City, which is also known as the Titanium Valley. All over the world, zirconium, titanium, nickel, niobium, and tantalum alloys are used in a wide range of industrial settings. All of them are easy for us to make.

We're proud to offer our ASTM R60702 zirconium crucible, which has walls that are 2 mm thick. This is what happens when you use high-tech ways to make things and strict rules for quality control. Each crucible goes through a lot of tests to make sure the sizes are correct to within ±0.1mm, the surface is smooth enough to be polished, and the material is more than 97.2% zirconium.

They are better than their competitors because they have low minimum orders that start at just one piece, fast shipping that only takes 5 to 7 days, and a lot of samples that can be used for testing. The plywood boxes we use keep the items safe and in shape while they are shipped all over the world. Many buyers in international markets can find a way to pay that works for them with T/T terms.

We do our best to meet quality standards around the world and make sure our clients are pleased. Thus, we have joined forces with groups in Australia, Korea, Germany, the United States, the United Kingdom, Malaysia, and all over the Middle East. We make sure that all of our products meet or go beyond what customers expect with our "quality-first" philosophy. We also offer quick technical support to customers both when they buy our products and when they are using them.

Good zirconium crucibles are built to last and do a great job. They will change the way you work with hot things. Our technical team can help you with your specific application needs. They will give you detailed specs, and then we'll make solutions that are unique to your business and meet all of your operational needs. The cutting-edge zirconium crucible technology from Freelong can help you make your manufacturing processes more efficient and your products better. Send us an email at jenny@bjfreelong.com to find out more.

References

1. American Society for Testing and Materials. ASTM R60702 Standard Specification for Unalloyed Zirconium for Chemical Applications. West Conshohocken: ASTM International, 2019.

2. Cox, B. "Zirconium Alloys in Nuclear Applications." Materials Science and Technology, vol. 28, no. 9-10, 2012, pp. 1132-1140.

3. Lustman, B., and F. Kerze. The Metallurgy of Zirconium. New York: McGraw-Hill Book Company, 1955.

4. Northwood, D.O. "The Development and Applications of Zirconium Alloys." Materials & Design, vol. 6, no. 2, 1985, pp. 58-70.

5. Franklin, D.G., et al. "Zirconium-Alloy Corrosion: A Review Based on an International Atomic Energy Agency Meeting." Nuclear Engineering and Design, vol. 119, no. 2-3, 1990, pp. 313-322.

6. Banerjee, S., and P. Mukhopadhyay. Phase Transformations: Examples from Titanium and Zirconium Alloys. Oxford: Elsevier Science, 2007.

_1745741768272.webp)

_1745394623005.webp)

_1744966046687.webp)

_1770280174853.png)