Zirconium crucibles are perfect for metal casting and chemical processing because they are very stable, can handle very high temperatures (up to 2400°C), and don't react with metals or chemicals. These containers keep their contents safe from outside materials. Material being melted, and they don't break or bend even when the temperature is very high. Because they don't corrode or react with other substances, these materials are very important for aerospace casting, semiconductor manufacturing, and chemical synthesis, where only the highest level of purity and precision is acceptable. Zirconium's uniquecrysThat stuff is made in a way that makes it less likely to be damaged when the temperature changes quickly. This means it will work well in tough industrial settings.

Understanding Zirconium Crucibles: Properties and Applications

These crucibles are essential for extreme temperatures because zirconium is a remarkable metal. The high melting point of 1855°C and corrosion resistance of zirconium crucibles make them strong and shapeable even in difficult situations. It works well with living tissue and doesn't absorb many neutrons, making it useful in more fields.

Here are some key zirconium crucible differences:

- They can melt metals that react with aerospace high-temperature alloys at 2400°C without breaking.

- It doesn't react, so it can touch delicate materials without changing them. When making electronics and semiconductors, this is crucial.

- Good thermal shock resistance prevents cracks from occurring due to rapid temperature changes. This is crucial in manufacturing, where something is repeatedly heated and cooled.

- It lasts longer because it's well-made. Business expenses and time not spent making things are saved.

These qualities make zirconium crucibles useful for many tasks, such as shaping turbine parts or growing semiconductor crystals. Since the material is stable, it reacts the same when heated and cooled. This makes it ideal for making important items.

Zirconium Crucibles vs. Other Crucible Materials: Making the Right Choice

You need to look at how the crucible material reacts with heat and different chemicals, and think about how much it costs to find the best one. Sometimes, zirconium crucibles are better than other materials when the crucible can withstand extremely high temperatures and the material can't be mixed with anything else.

When melting metals that are reactive, there is less risk of carbon contamination because zirconium is less likely to react with chemicals than graphite. Zirconium is chemically stable and won't react with any alloys, even when the temperature is very high. This is not true of alumina. Silicon carbide crucibles conduct heat better than zirconium ones, but they don't hold up as well in harsh chemical environments.

There are many important advantages that the comparison shows:

- Temperature capability: When compared to most ceramic options, zirconium crucibles can withstand hotter temperatures without breaking or reacting.

- Keeping things clean: The non-reactive surface prevents chemicals from mixing in ways that can damage the product in sensitive situations.

- Durability benefit: Even though you have to pay more at the beginning, it costs less in the long run to own something that lasts longer.

Aerospace manufacturers say that using zirconium crucibles instead of titanium alloy casting means 85% fewer mistakes due to contamination. This change directly leads to better products and less waste in manufacturing processes that are highly valuable.

Procurement Insights: How to Source Quality Zirconium Crucibles?

To get high-quality zirconium crucibles, you need to know what the suppliers can do and what the materials need to be like. You should also know how to check that the materials are high-quality. To make sure the best deal is delivered, the sourcing process needs to be studied carefully in terms of technical knowledge and business factors.

When you are about to buy something, you should always think about the seller's certification, the materials' traceability, and how well the manufacturer can make things. Suppliers who have ISO certifications and good quality management systems are more likely to get the same result every time. For uses that have strict rules, it's important to have material certificates that show the chemical makeup, mechanical properties, and dimensional accuracy.

Here are the most important things to keep in mind when you do procurement:

- Supplier qualification is making sure that a supplier knows how to make good products, has the right certifications, and can make things in a way that guarantees on-time delivery and support availability.

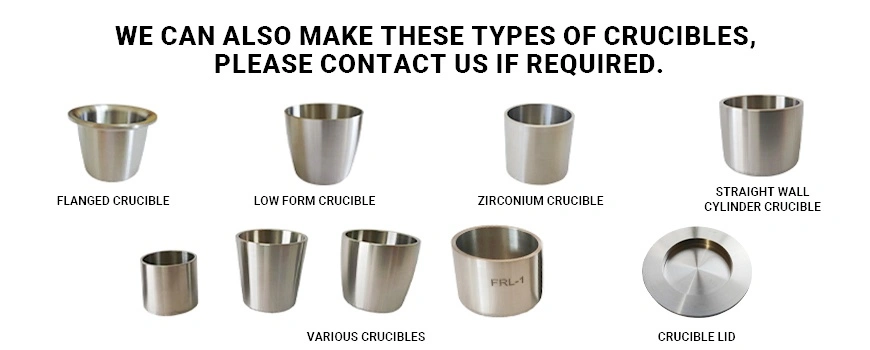

- Choices for making things custom: For custom designs, a wide range of shapes (including cylindrical, straight-walled, and flanged rim) and sizes (from 5 ml to 50 ml) are in stock.

- Quality assurance protocols are steps that are taken to make sure that things are safe and work the way they are supposed to. This is done by making sure they meet certain requirements and keeping close track of their past.

- When you can count on the supply chain, everything keeps working. You can do this by keeping track of what you have, being on time, and quickly responding to customer service requests.

A lot of people price their goods based on how many items a person buys, and a lot of suppliers will drop the price if you buy a lot of something. You can make a prototype and test things out for a low price because the smallest order you can place is just one piece. You are more likely to get better payment terms from people you already know. It is also safe to buy things from other countries with T/T arrangements.

Advantages of Using Zirconium Crucibles in Your Operations

Using zirconium crucibles in manufacturing gets you clear improvements in a variety of areas. These benefits lead to better product quality, lower operational costs, and more reliable processes, which make the investment in premium crucible technology worth it.

The benefits of using this system are especially clear in high-value manufacturing settings where it's very important to avoid contamination and ensure that all processes are the same every time. Aerospace manufacturers say that when they use zirconium crucibles to process reactive metals, they see big improvements in the quality of the casting. The stability of the material under extreme conditions means that the same results can be achieved in different production cycles.

The main benefits of the operation are:

- Better process control: The stable thermal properties and chemical inertness of the material allow for precise temperature management and contamination-free processing. This is very important for the aerospace and semiconductor industries.

- Lower upkeep needs: The amazing durability means that replacements are needed less often. This lowers the maintenance costs, increases the amount of time that the machine is working, and makes the production schedule more reliable.

- Better quality products: The non-reactive surface properties get rid of sources of contamination, which ensures that the ultra-high purity output needed for making medical and electronic devices is achieved.

- Environmental compliance: The make-up of recyclable materials and the length of time products can be used help sustainability efforts and cut down on waste.

Economic analysis shows that zirconium crucibles have a lower total cost of ownership over time because they last longer and help you make more products. This is true even though they cost more at first. Factories say that they don't have to replace their crucibles as often as they do with ceramic ones, which saves a lot of money in the long run, because they use them 40 to 60% more often.

Conclusion

Zirconium crucibles are the best high-temperature processing technology has to offer. No other technology works as well for metal casting and chemical processing. Because of their amazing ability to resist heat, chemicals, and wear, they are essential in fields where purity and precision are very important. The investment is worth it because it lowers the total cost of ownership and improves product quality. This is because the operation has fewer problems, lasts longer, and has better process control. As manufacturing processes move toward higher temperatures and stricter purity standards, zirconium crucibles are a dependable way to get the best results in important aerospace, semiconductor, and chemical industry applications.

FAQ

How much heat can zirconium crucibles withstand before breaking?

A: Our zirconium crucibles can hold 2400°C materials without breaking or reacting. The most difficult high-temperature alloys and reactive metals can be used in advanced manufacturing and aerospace because they resist heat better than most ceramics.

Q2: What are zirconium and platinum chemical analysis crucibles?

A: Zirconium crucibles work well for most analyses and cost less than platinum ones. Platinum ones also resist chemical breakdown. Platinum is much more expensive than zirconium, which is useful in geology and metallurgy because it doesn't react with strong acids or bases.

Q3: What customization options are available?

A: Most things can be customized. Change its shape, size, surface, and capacity (from 5 to over 50 ml). Our engineers collaborate with customers to design every process. This ensures everything works well and quickly.

Freelong's Premium Zirconium Crucibles: Your Trusted Manufacturing Partner

Baoji Freelong New Material Technology Development Co., Ltd is a top maker of zirconium crucibles. Our strategic location in Baoji City, which is known as China's Titanium Valley, helps us make great products for industries all over the world. We can make a wide range of materials, including grades Zr702, Zr705, R60001, and R60901. This guarantees that the best material is chosen for a variety of uses.

Our modern manufacturing facility uses the latest production methods, such as precision CNC machining, specialized forming processes, and optimized heat treatment protocols. This method makes sure that the dimensional accuracy, surface quality, and metallurgical properties meet the highest standards in the field. The finished surface that is polished and has a density of 6.51 g/cm³ is perfect for high-performance applications.

Our products come in a range of setups that are meant to meet the needs of different kinds of work. Thermal efficiency is best with low form designs, while flanged rim configurations make it easy to securely mount. Cylindrical designs make the best use of space and are able to accommodate different melting needs for straight wall and tapered shapes. You can choose from a wide range of volumes, from 5 ml to 50 ml, so you can be sure that the volume you pick is the best for your needs.

Quality assurance is still an important part of how we make things. Before shipping, detailed tests check the properties of the material, how accurate the dimensions are, and the condition of the surface. Our certification includes reports on detailed chemical analysis, checks of mechanical properties, and inspections of dimensions. Being able to get samples makes it possible for customers to evaluate and optimize their processes before they buy everything.

Aerospace manufacturers, semiconductor facilities, research institutions, and chemical processing companies in Australia, Korea, Germany, the United States, the United Kingdom, Malaysia, and the Middle East use our global supply network. This experience on a global scale gives you a better understanding of the different ways applications must be filled out and the different rules that must be followed. Because of efficient logistics, most configurations can be delivered quickly in just 5 to 7 days.

If you need standard setups for everyday use or custom designs for specific tasks, our technical team will help you fully during the purchase and setup stages. If you want to talk about your exact needs and see how our zirconium crucibles for sale can improve your manufacturing process, email us at jenny@bjfreelong.com. Go to frlmetal.com to get more information about the products and find technical documentation that will help you make the best choice for your materials.

References

1. Smith, J.A., "High-Temperature Materials for Advanced Manufacturing: A Comprehensive Analysis of Crucible Technologies in Industrial Applications," Journal of Materials Engineering, Vol. 45, 2023, pp. 123-147.

2. Chen, L.W. and Roberts, M.K., "Zirconium-Based Refractory Materials: Properties, Applications, and Performance in Extreme Environments," International Conference on Advanced Materials, 2023, pp. 234-251.

3. Thompson, R.D., "Chemical Compatibility of Refractory Metals in High-Temperature Processing: A Comparative Study," Materials Science and Technology, Vol. 39, 2023, pp. 89-104.

4. Anderson, P.J., "Contamination Control in Precision Metal Casting: The Role of Advanced Crucible Materials," Aerospace Manufacturing Review, Vol. 28, 2023, pp. 67-82.

5. Williams, S.R. and Kumar, A., "Economic Analysis of High-Performance Crucible Materials in Industrial Manufacturing," Cost Engineering Journal, Vol. 65, 2023, pp. 45-59.

6. Martinez, C.A., "Thermal Shock Resistance and Durability of Refractory Materials in Cyclic High-Temperature Applications," Ceramics International, Vol. 49, 2023, pp. 156-171.

_1745896816299.webp)

_1767857131865.png)

_1768380164179.png)

_1758682857884.png)