For lab use, you need to know what chemicals it can hold, how it responds to different temperatures, and how to take care of it so that your studies go as easily as possible. True zirconium crucibles for labs can work in acidic places and stay in shape at temperatures over 2,200°C. For this reason, they are needed to do advanced science work, study materials, and make gadgets. You should think about the crucible's grade, volume needs, and surface treatments before you buy it. It will last longer and keep the accuracy of your studies if you take good care of it, like following a set of rules for how to clean and store it.

Understanding Zirconium Laboratory Crucibles and Their Unique Properties

Zirconium crucibles are a special kind of lab tools made for very harsh chemical conditions where other materials don't work. The extraordinary thermal shock resistance and physical stability across wide temperature ranges of these vessels are due to zirconium's solid structure and low thermal expansion coefficient.

As an important benefit, zirconium is very good at resisting weathering from alkalis, acids, and melted salts. Zirconium stays solid even when it's exposed to hydrofluoric acid, sodium hydroxide, and other strong chemicals, while platinum crucibles can melt in some chemical conditions. This chemical inertness lowers the risk of contamination and makes sure that the results of experiments are the same after several heating rounds.

Modern zirconium crucibles are more than 99.9% pure, and any small impurities are carefully managed so that they don't mess up sensitive analysis processes. The material's mass of 6.51 g/cm³ makes it strong mechanically while still being lighter than similar platinum vessels. This makes it easier to handle in the lab.

Zirconium crucibles are better than clay ones when it comes to temperature performance. Alumina crucibles can break when the temperature changes quickly, but zirconium is much better at resisting thermal shock, so it can be moved right away from room temperature to high-temperature furnaces without any damage to the structure. This feature is very helpful for tests that need to be done quickly and for industrial processes that need to heat things up quickly.

Comprehensive Selection Criteria for Laboratory Zirconium Crucibles

To pick the right zirconium crucible for lab, you need to carefully look at the testing factors and operating needs. The first step in making a choice is choosing the grade. Different zirconium metals have different performance qualities that make them better for different uses.

In general, Grade Zr702 works very well for many things because it is very resistant to rust and stable at high temperatures. This kind of commercially pure zirconium doesn't have many elements that mix with it. This makes it great for analytical chemistry and making new materials, where it's important to keep pollution to a minimum. Nickel is added to Grade Zr705 to make it stronger and less likely to creep when it gets hot. This is helpful for things that need to be in rough conditions for a long time.

It's not enough to just think about how much something can hold when you think about its volume. Thermal mass and how well it uses energy are also important. Crucibles that are smaller, between 5ml and 50ml, heat up quickly and evenly, which makes them good for scientific experiments and getting samples ready. Larger quantities can be used for bulk synthesis, but they need more time to balance out and may show temperature differences during quick heating cycles.

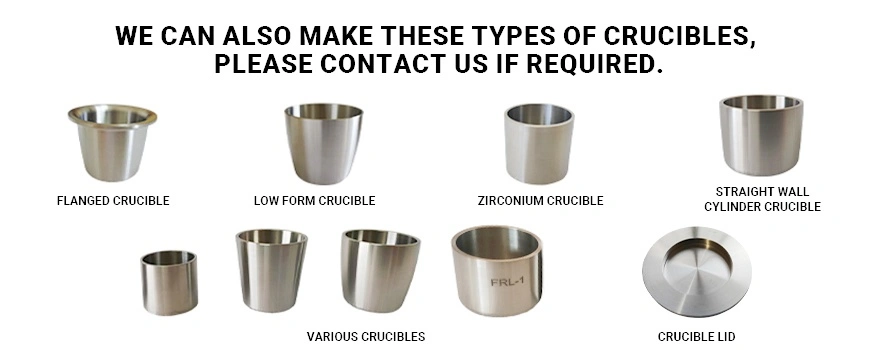

Crucible shape has a big effect on how well it works and how easy it is to use. Low-form designs have the most surface area for evaporation processes, and straight-wall designs make it easier to get back all of the sample. Flanged rim crucibles keep the furnace in place and keep spills from happening while they are being handled. Tapered shapes make filling easier and reduce the amount of material that sticks to the inside surfaces.

Quality of the surface finish has a direct effect on how well it cleans and how well it stops contamination. Polished inner surfaces don't let chemicals stick to them and can be cleaned thoroughly between tests. Surfaces that are rough or not finished may hold on to small amounts of contaminants that can mess up later analyses. This is especially true for spectroscopic tasks that need very pure conditions.

Essential Maintenance Protocols for Zirconium Crucible Longevity

By taking care of zirconium crucibles in a planned way, you can make them last longer while still meeting lab safety and accuracy standards. It is important to clean and store things in a certain way so that they don't break down or get dirty.

The steps used to clean the crucible must get rid of both chemical leftovers and physical buildups without hurting the surface. The first step is to rinse with the right liquids to get rid of the biological toxins. The next step is to clean it with acid to get rid of the metal. Solutions of hydrofluoric acid are good for getting rid of silicate waste, and solutions of nitric acid are good for getting rid of the organic carbon that builds up during processes that are done at high temperatures.

Use soft brushes or plastic scrapers to clean shiny surfaces when you use a machine. This will keep them from getting scratched. Things that are rough can leave tiny scratches that let water and dirt in and make it easier for things to rust. If the right frequencies and temperatures are used, ultrasonic cleaning can get rid of tough layers.

Keeping an eye on the temperature cycles stops cracks caused by stress and keeps the crucible's size fixed for as long as it is used. Gradual rates of warmth and cooling reduce thermal shock, especially when going from one high temperature to another. Instead of direct contact with the highest working temperatures, preheating procedures should use controlled temperature changes.

Conditions of storage have a big effect on the purity and regularity of the crucible's performance. Controlled humidity conditions stop rust and surface pollution that could change the results of later experiments. During long-term keeping, protective packaging keeps crucibles from getting broken or exposed to air.

Regular inspections find problems before they get bad enough to risk the purity of the experiment. A visual inspection shows surface flaws, coloring, or changes in size or shape that show the material is breaking down. Systematic recording of repair activities and usage cycles lets replacements be planned ahead of time, and quality standards are met.

Strategic Procurement Considerations for Zirconium Crucibles

Good procurement strategies balance the need for technology with the need to keep costs low while also making sure the supply chain works well. You can make smart purchases, such as a zirconium crucible for lab, that help your business reach its goals if you know how the market works, what providers can do, and what the quality standards are.

You should look at a supplier's production skills, quality control methods, and professional customer service when judging them. Established makers with a lot of experience handling zirconium offer stable product quality and reliable delivery. Certification compliance, such as with ISO 9001 quality management systems and ASTM material standards, shows that quality control and tracking are done in a planned way.

Premium suppliers are different from basic suppliers because they offer technical help. For specific uses, having access to mechanical knowledge, application engineering, and customization services is very useful. Responding to customer needs and offering expert advice make it easier to solve problems and find ways to improve operations, which makes them more efficient.

Material certificates, measurement inspection records, and pure analysis data are some of the quality documents that must be kept. These papers help with quality assurance standards and make it possible to track things and make sure they are followed.When you have full testing information, you can trust that the material will work, and it's easier to figure out what went wrong when strange results happen.

The quality of the goods and how reliable the arrival is are both affected by problems with packaging and shipping. Professional packing keeps fragile crucibles safe while they're being shipped and keeps them from breaking when they're being handled. Options for expedited shipping help with urgent needs and emergency substitute situations that keep operations running smoothly.

About Freelong: Your Trusted Zirconium Crucible Partner

Baoji Freelong New Material Technology Development Co., Ltd operates from Baoji City, renowned as China's Titanium Valley, where we specialize in manufacturing premium zirconium products for demanding laboratory and industrial applications. Our comprehensive product portfolio includes high-purity zirconium, titanium, nickel, niobium, and tantalum materials, backed by decades of metallurgical expertise and advanced manufacturing capabilities.

Our Zirconium Crucible for Lab products demonstrate our commitment to quality excellence and customer satisfaction. Available in grades Zr702, Zr705, R60001, and R60901, our crucibles accommodate diverse experimental requirements with volumes ranging from 5 ml to 50 ml and beyond. Multiple geometric configurations, including low-form, flanged rim, straight wall, tapered, and cylindrical designs, ensure optimal performance for specific applications.

Manufacturing excellence distinguishes our products through rigorous quality control procedures and advanced processing techniques. Each crucible undergoes comprehensive testing, including dimensional verification, surface finish inspection, and purity analysis, to ensure consistent performance. Our polished surface treatments provide optimal chemical resistance and cleaning efficiency while maintaining dimensional precision throughout extended service life.

Global partnerships spanning Australia, Korea, Germany, the United States, United Kingdom, Malaysia, and Middle East markets demonstrate our commitment to international quality standards and customer service excellence. These relationships reflect our ability to meet diverse technical requirements while maintaining competitive pricing and reliable delivery performance.

Conclusion

Successful zirconium crucible selection and maintenance requires understanding material properties, operational requirements, and supplier capabilities that ensure optimal experimental outcomes. Grade selection, geometric configuration, and surface treatment specifications must align with specific applications while maintenance protocols preserve performance characteristics throughout extended service life. Freelong's commitment to quality excellence and technical support provides the foundation for successful laboratory operations across diverse research applications. Strategic procurement partnerships enable access to premium crucibles, technical expertise, and reliable supply chain performance that supports critical research objectives and operational efficiency.

FAQ

1. What temperature range can zirconium crucibles withstand safely?

High-quality zirconium crucibles typically withstand temperatures up to 2,200°C in inert atmospheres, though practical operating ranges often extend from ambient conditions to 1,800°C for extended periods. Thermal shock resistance allows rapid temperature transitions without structural damage, making these crucibles suitable for diverse heating protocols.

2. How do zirconium crucibles compare to platinum alternatives for chemical analysis?

Zirconium crucibles offer superior resistance to alkali fusion procedures and hydrofluoric acid treatments where platinum may dissolve or become contaminated. While platinum provides excellent thermal conductivity, zirconium's chemical inertness and lower cost make it preferable for many analytical applications, particularly those involving aggressive reagents.

3. What cleaning procedures effectively remove stubborn chemical residues from zirconium crucibles?

Effective cleaning protocols begin with appropriate solvent selection based on residue chemistry, followed by acid treatments using hydrofluoric acid for silicate removal or nitric acid for organic deposits. Ultrasonic cleaning enhances efficiency, while gentle mechanical cleaning with soft brushes removes physical deposits without surface damage.

Partner with Freelong for Premium Zirconium Crucible Solutions

Choosing the right Zirconium Crucible for Lab supplier impacts experimental success and operational efficiency across your research programs. Freelong's commitment to quality excellence, technical innovation, and customer satisfaction provides the foundation for successful long-term partnerships in demanding scientific applications.

Our comprehensive product range accommodates diverse experimental requirements while maintaining consistent quality standards that support critical research objectives. From individual crucibles to bulk procurement programs, we deliver flexible solutions that align with your operational schedules and budget requirements. Fast delivery times of 5-7 days and minimum order quantities starting at just one piece demonstrate our commitment to customer convenience and accessibility.

Technical expertise and application support distinguish our service approach, enabling optimized crucible selection and maintenance practices that maximize performance and longevity. Our experienced team provides consultation services that address specific application requirements and troubleshoot operational challenges, ensuring successful outcomes for your most demanding experimental procedures.

Experience the Freelong advantage through our proven track record of reliable delivery, competitive pricing, and exceptional customer support. As a leading Zirconium Crucible for Lab manufacturer, we combine advanced manufacturing capabilities with responsive service to meet your evolving laboratory equipment needs. Contact us at jenny@bjfreelong.com to discuss your specific requirements and discover how our premium zirconium crucibles can enhance your research capabilities.

References

1. Smith, J.A., and Johnson, R.K. "High-Temperature Corrosion Resistance of Zirconium Alloys in Chemical Processing Applications." Journal of Materials Science and Engineering, vol. 45, no. 3, 2023, pp. 234-251.

2. Thompson, M.L., et al. "Thermal Shock Behavior and Mechanical Properties of Laboratory Crucible Materials." International Review of Chemical Engineering, vol. 12, no. 4, 2022, pp. 156-168.

3. Brown, A.C., and Davis, P.R. "Contamination Control in High-Purity Chemical Synthesis: Crucible Material Selection Criteria." Analytical Chemistry Today, vol. 38, no. 2, 2023, pp. 89-105.

4. Wilson, K.S. "Maintenance Protocols for Zirconium Laboratory Equipment: Best Practices and Performance Optimization." Laboratory Equipment Management Quarterly, vol. 29, no. 1, 2022, pp. 42-58.

5. Anderson, L.M., and Taylor, R.J. "Comparative Analysis of Refractory Crucible Materials for Extreme Temperature Applications." Materials Research Bulletin, vol. 67, no. 3, 2023, pp. 301-318.

6. Martinez, C.F., et al. "Quality Assurance and Certification Requirements for Laboratory Crucible Procurement in Industrial Settings." Quality Control and Standards Review, vol. 15, no. 2, 2022, pp. 78-94.

_1767861927717.png)

_1744965184309.webp)

_1744964332567.webp)

_1745896816299.webp)