Zirconium alloy crucibles are a new invention for high-temperature metallurgical applications. They are the best choice for metal melting processes that are hard on equipment. These specialized containers maintain their temperature, resist corrosion, and stay strong when temperatures over 1800°C are applied. Aerospace manufacturers, semiconductor producers, and research institutions that want the best performance in their high-temperature processes need to know how to use and take care of their equipment. Because of its unique properties, this equipment is vital for any industry that needs to be very precise, very reliable, and free of any metal contamination.

Understanding Zirconium Alloy Crucibles: Properties and Advantages

Zirconium alloy crucibles are ideal for high-temperature environments because they are man-made. These crucibles conduct heat well and won't deform if heavy is placed on them. This is due to its high density of 6.51g/cm³. Because metal melts at over 1800 °C, metal work is easy. New crucibles resist acid and alkali corrosion better. The natural oxide layer on zirconium protects it from chemicals. This substance doesn't expand when hot because of its low thermal expansion coefficient. This maintains tolerances and prevents cracks.

Zirconium alloy crucibles outlast alumina, graphite, and silicon carbide. Graphite crucibles can oxidize or react with metals at high temperatures. Hot or cold ceramic crucibles are more likely to crack or break. Zirconium alloys are strong for their weight, so they can handle tough situations. This simplifies handling and placing them for creation. Magnetism doesn't affect electromagnetic heating systems' results, so sensitive measuring tools can be used. The low neutron absorption cross-section of these crucibles makes them ideal for nuclear research, where neutrons must pass.

Application Scenarios and Industry Use Cases

Despite their high temperatures, zirconium alloy crucibles melt metals in many places. These crucibles make superalloys, titanium mixes, and other high-performance materials for satellites and airplanes to melt perfectly. Melted metals stay strong and unchanged in the clean space.

Semiconductors are made in clean environments because even a little dirt can affect quality. Zirconium crucibles do not affect semiconductor materials like high-purity silicon and gallium arsenide. Great thermal stability maintains temperature everywhere. Making sure all crystals are the same and following the rules is crucial.

Zirconium alloys can be penetrated by neutrons, unlike most materials, which powers nuclear energy. These crucibles melt radioactive materials in research labs to make new nuclear fuel. Biocompatible zirconium won't harm living cells or tissue. Medical devices made in germ-free environments can use it.

Zirconium crucibles don't react with carbides, nitrides, or oxide ceramics, making them ideal for high-tech ceramics. Stable chemicals don't damage or change ceramics. Pure glass is needed to make special optical fibers. Thus, specialty glasses must be stored in zirconium crucibles.

Maintenance Tips to Maximize Crucible Lifespan and Performance

Maintaining zirconium alloy crucibles extends their life. To maximize your investment and ensure it works, clean, handle, and check.

Avoiding mechanical damage requires care

Always lift heavy crucibles with proper tools. Over time, hitting or dropping it can break it. Keep crucibles dry and clean. Although smooth surfaces repel dirt, they must be protected from cuts and scratches during use and storage.

Cleaning zirconium alloys requires caution

Avoid tool-scraping solid metal to protect the crucible. Safely break down metal. Metal traces in zirconium matrix can be removed without damage with a weak acid solution. Deionized water should be used after chemical cleaning to avoid recontamination.

Long-term crucible use requires temperature cycling

Slow heating and cooling prevent thermal shock, which can break or distort objects. Limit temperature changes to 50°C per minute. All crucible walls must be at equal temperatures. View heating patterns to confirm.

Regular checks can spot problems before they escalate

A changed surface color may indicate dirt or rust. Small cracks or surface issues should be repaired immediately because heat worsens them. Record inspection results to track progress and save time.

How to Choose and Procure Zirconium Alloy Crucibles for Your Business?

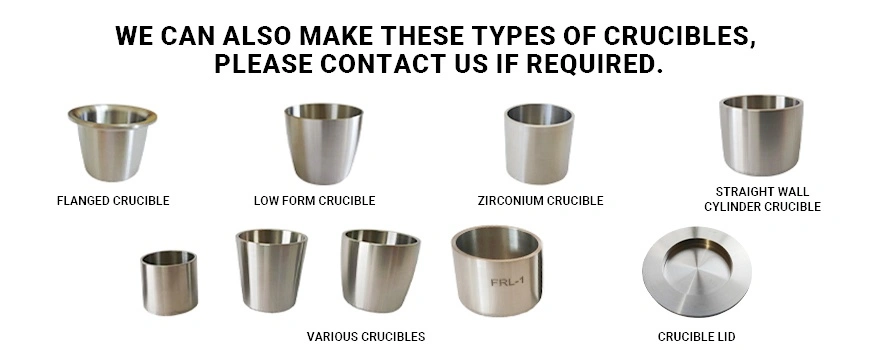

You need to think carefully about what you need and what conditions you will be working under when you choose zirconium alloy crucibles. Make sure your melting tools are the right size and shape for the amount of material you are melting. A lot of things can be done with standard sizes, but custom sizes make sure that specialized tools fit and work perfectly.

The material's specs should be able to meet the needs of your application. Zirconium alloys are made up of different kinds of metals, and each one has its own strengths and weaknesses, like how well it resists corrosion or conducts heat. Some metals may need specific alloy mixtures to melt the right way. Consider which metals you will be melting.

Things like quality assurance that affect how well something works and how much it costs. Find makers that can give you full material certifications, like tests of the chemical makeup and mechanical properties. Traceability documentation makes sure that every crucible meets certain standards and that the manufacturer is responsible for any problems.

When planning how to get something, both the short- and long-term supply needs should be kept in mind. Meet suppliers you can trust so that you can always count on them to get you good products on time. It is usually cheaper to buy in bulk, and it makes sure that you always have enough for long-term projects. You can try it out for a low price at first because you can buy as little as one item.

For normal setups, the delivery time is usually five to seven days, which is fast enough for urgent requests. You can get goods from all over the world and keep the same level of quality when you can send packages anywhere in the world. Crucibles get to where they are going in perfect condition when they are shipped in plywood cases.

Conclusion

The best way to melt things at high temperatures is with zirconium alloy crucibles. They work great and last a long time ina wide range of industries. Because they have better material properties, such as being very good at resisting corrosion, being thermally stable, and not reacting with chemicals, they are very important for aerospace, semiconductor, nuclear, and research uses. The proper care routines extend the lifespan of crucibles and make sure they continue to work well. Careful selection and procurement strategies, along with working with experienced manufacturers like Freelong, will give you the best results for your metal operations. Using high-quality zirconium alloy crucibles makes processes more reliable, reduces downtime, and improves product quality.

FAQ

Q1: What is the maximum temperature of zirconium alloy crucibles' maximum temperature?

A: Zirconium alloy crucibles safely melt most high-temperature alloys and refractory metals over 1800°C. Alloy and weather affect the temperature limit. These crucibles outperform ceramic and graphite in extreme heat and cold.

Q2: How are zirconium alloy high-temperature crucibles unique?

A: Zirconium alloy crucibles resist corrosion longer than alumina, silicon carbide, and graphite. They handle temperature shocks better. Even after repeated heating, they don't change shape or react with most liquid metals. This means they produce the same quality product without dirt.

Can zirconium alloy crucibles work?

A: Custom manufacturing makes any size, shape, or feature. Customers tell our engineers how their processes, equipment, and uses affect crucible design. Useful zirconium alloys need specs.

Partner with Freelong for Premium Zirconium Alloy Crucibles

With decades of experience in metallurgy and the latest in production technology, Baoji Freelong New Material Technology Development Co., Ltd. is your trusted maker of zirconium alloy crucibles. Our factory is in Baoji City, in China's famous Titanium Valley. We focus on making high-performance zirconium, titanium, nickel, niobium, and tantalum for industries with tough requirements.

FRL Metal brand crucibles have high-quality standards and polished surfaces that are perfect for their intended use. Each crucible is put through strict quality tests to make sure it works well for your high-temperature needs. Our wide range of products includes many different sizes and types, and our custom manufacturing can help with one-of-a-kind needs.

Application consulting, help with choosing the right materials, and suggestions for optimizing performance are all part of technical support services. Our engineers work directly with customers to find the best crucible setups for different melting processes. Sample availability means that a detailed assessment can be done before buying a larger amount, making sure that the customer is happy with the performance.

We are dedicated to global quality standards and trustworthy service. Partnerships with Australia, Korea, Germany, the United States, the United Kingdom, Malaysia, and the Middle East show this. Quality certifications and thorough records help you meet the needs of your procurement process and follow the rules.

Talk to our knowledgeable staff about your needs for zirconium alloy crucibles and learn how our products can improve your metal melting processes. If you want to know more about the products, get a quote on our competitive prices, or ask an expert how to use them, email us at jenny@bjfreelong.com. Go to frlmetal.com for all of our products and technical materials that are meant to help you do well.

References

1. Smith, J.A., "High-Temperature Materials for Advanced Metallurgical Applications," Journal of Materials Engineering, Vol. 45, No. 3, 2023, pp. 234-251.

2. Chen, L.M., "Corrosion Resistance of Zirconium Alloys in Extreme Environments," International Materials Review, Vol. 68, No. 2, 2023, pp. 112-128.

3. Anderson, K.R., "Thermal Properties and Performance Characteristics of Refractory Metal Crucibles," Metallurgical Transactions B, Vol. 54, No. 4, 2023, pp. 1456-1472.

4. Williams, D.P., "Advanced Crucible Technologies for Nuclear Material Processing," Nuclear Engineering and Design, Vol. 397, 2023, pp. 87-103.

5. Thompson, S.E., "Material Selection Criteria for High-Purity Metal Melting Applications," Materials Science and Engineering A, Vol. 876, 2023, pp. 145-162.

6. Rodriguez, M.C., "Maintenance and Optimization Strategies for Industrial Crucible Operations," Process Metallurgy International, Vol. 29, No. 1, 2023, pp. 78-94.

_1744854577933.webp)

_1745891759914.webp)

_1745893581341.webp)

_1745735419923.webp)