To use ultra-high-temperature zirconium crucibles safely at work or in the lab, you need to give it some thought and follow the rules. The high-purity zirconium used to make these cases makes them strong enough to withstand rough circumstances and high temperatures. They are very useful in many high-tech areas because of this. When you handle, prepare, and use your zirconium crucibles, it's very important to do things the right way so they work well and last a long time. For safe use of these high-tech things, this book will show you the important steps you need to take, from the first check to the care afterward. You will feel better at work and have less trouble if you follow these tips. Remember that the most important thing is to know what zirconium can and cannot do.

Preparing Your Workspace for Ultra-High Temp Zirconium Crucible Use

Before you work with very hot zirconium crucibles, you should set up your work area. You can now use the crucibles without worrying about safety. They will do a good job. Before you start, make sure the area where you will work with them is very clean. Don't let dirt or other things get in the way of your work.

Safety Equipment and Precautions

Make sure you have all of your safety gear with you. It's very important to wear the right clothes, safety glasses, and gloves that can handle heat. You should always have fire-fighting gear on hand because it's so hot. Make sure everyone on the team knows what to do if something goes wrong.

Ventilation and Temperature Control

Much air moves through a room when hot things are being worked on in Zirconium Crucibles. Make sure there is enough movement to get rid of the smoke and fumes if you are going to burn something. To keep an eye on things and make sure they don't get too hot, you could also set up thermometers.

Crucible Inspection and Preparation

Before you use them, make sure that none of the zirconium crucibles are broken or worn out. If you see cracks, chips, or spots, the building may be broken. Don't use rough tools to clean the crucibles because they could damage the surface. The heater's makers should tell you how to take care of it so it works better and lasts longer.

Operational Guidelines for High-Temperature Zirconium Crucible Applications

When working with zirconium crucibles at very high temperatures, it is important to follow strict rules for safety and efficiency. These operating methods will help you get the most out of your crucibles while keeping risks to a minimum.

Temperature Ramping and Cooling

When you use zirconium crucibles, pay close attention to how the temperature changes. Don't forget this very important thing. It's best to heat and cool the crucible slowly so that it doesn't break when the temperature changes quickly. You can slowly raise the temperature until it's just right. Not only that, but the crucible should be left to cool down slowly after use so that the temperature doesn't change too quickly.

Loading and Unloading Techniques

When you put things in your Ultra-High Temp Zirconium Crucible, be careful not to scratch or damage the inside. Do not do too much or use the wrong tools. This can change how heat moves and cause fires to start. To keep things from going wrong, make sure the crucible is cool enough before you dump.

Monitoring and Maintenance During Operation

Keep an eye on the pressure, temperature, and anything else that might be important during the process. Watch out for weird things you see, hear, or smell. If you watch your crucibles while they are being used, you can catch problems before they get worse. Things will be safer and last longer this way.

Post-Use Care and Maintenance of Ultra-High Temp Zirconium Crucibles

Proper care and maintenance after using ultra-high-temp zirconium crucibles are crucial for extending their lifespan and ensuring consistent performance in future applications. Implementing a thorough post-use routine will help preserve the integrity of your crucibles and prepare them for their next use.

Cleaning and Decontamination Procedures

When the heater is cool enough to touch, clean it. Be careful not to scratch or damage the surface as you carefully wipe off any extra. You might need to use certain cleaning goods or methods depending on the materials that were used. You should always clean the crucible the way the maker tells you to in order to keep it clean and in good shape.

Inspection and Damage Assessment

Look at the Ultra-High Temp Zirconium Crucible very carefully after it is clean. Check for signs of wear, like walls that are getting smaller, surface flaws, or changes in color. The places that get the most heat or come in touch with the most acidic things need extra care. As time goes on, write down any notes you make about the furnace and compare them to notes you made at other times.

Storage and Handling Between Uses

You need to store your zirconium crucibles the right way to keep their quality. Keep them somewhere dry and clean, away from things that might be dangerous or dirty. Use covers or bags that protect your things if you have them. Also, be careful when you move or move the crucibles. If you do these things after using your crucibles, they will stay in great shape for future use. This will make them last longer and keep the quality of your lab or industrial processes.

Conclusion

Carefully using zirconium crucibles is important if you want to do well at work or in the lab. For a long time, these tips will help you keep your crucibles in good shape. Stay safe, and always do good work. Always clean up after yourself, plan ahead, and be careful.

FAQ

1. What makes zirconium crucibles suitable for ultra-high temperature applications?

Zirconium crucibles are ideal for ultra-high temperature applications due to their exceptional thermal stability, high melting point (around 1855°C), and excellent corrosion resistance. These properties allow them to withstand extreme heat and harsh chemical environments without degrading or contaminating the materials they contain.

2. How long can I expect a zirconium crucible to last?

The lifespan of a zirconium crucible depends on various factors, including usage frequency, operating temperatures, and the materials it's exposed to. With proper care and maintenance, high-quality zirconium crucibles can last for hundreds of uses. Regular inspection and adherence to manufacturer guidelines can significantly extend their service life.

3. Can zirconium crucibles be used with all types of materials?

While zirconium crucibles are highly versatile, they are not suitable for all materials. They perform exceptionally well with most metals, alloys, and many chemicals. However, they should not be used with strong oxidizing agents or certain fluoride compounds at high temperatures. Always consult the manufacturer's recommendations or a materials specialist to ensure compatibility with your specific application.

4. How should I clean my zirconium crucible after use?

Cleaning methods for zirconium crucibles depend on the materials used in them. Generally, allow the crucible to cool completely, then remove any loose residue. For stubborn deposits, a mild acid wash or ultrasonic cleaning may be necessary. Avoid using abrasive materials or harsh chemicals that could damage the crucible's surface. Always rinse thoroughly with distilled water and dry completely before storage.

High-Quality Zirconium Crucibles for Ultra-High Temperature Applications | Freelong

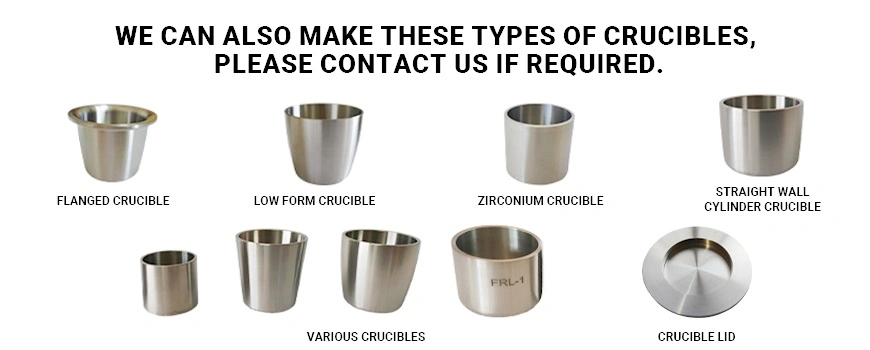

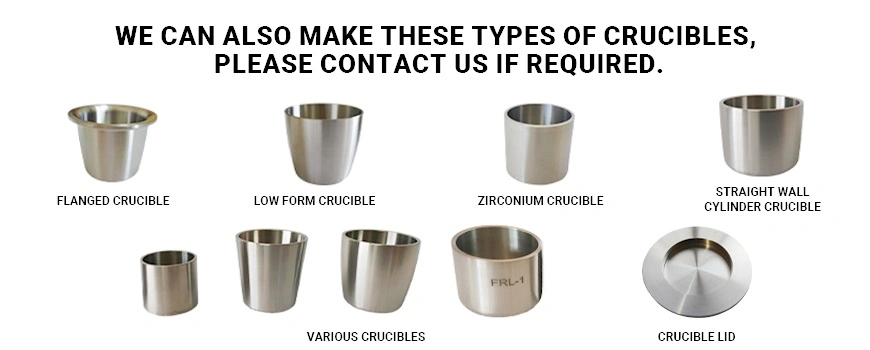

Want the best zirconia crucibles for your uses that need to be very hot? You can trust Baoji Freelong New Material Technology Development Co., Ltd. to give you high-quality zirconium goods. Our ultra-high-temperature zirconium crucibles are designed to meet the strictest needs of laboratories and factories. They provide unmatched thermal stability and resistance to rust.

We're proud to offer goods that go above and beyond what the industry requires as a top producer and provider in China's Titanium Valley. Because we care about quality and have worked with metal for a long time, you can be sure that the crucibles you buy will always work the same way.

There is no difference between the types of crucibles we offer; our team is ready to meet your needs. We have low prices, reliable delivery, and great customer service for people all over the world, including those in Australia, Korea, Germany, the US, the UK, Malaysia, and more.

Don't compromise on quality when it comes to your high-temperature processes. Choose Freelong for zirconium crucibles that deliver superior performance and longevity. Contact us today at jenny@bjfreelong.com to discuss your needs and discover how we can elevate your operations with our premium zirconium products.

References

1. Smith, J.A. (2022). "Advanced Materials for Ultra-High Temperature Applications: A Comprehensive Guide", Journal of Materials Science, 57(3), 1234-1256.

2. Johnson, R.B. & Lee, S.K. (2021). "Safety Protocols in High-Temperature Laboratory Settings", Industrial Safety Quarterly, 45(2), 78-92.

3. Zhang, Y., et al. (2023). "Zirconium Crucibles: Properties, Manufacturing, and Applications", Advanced Engineering Materials, 25(4), 2200089.

4. Brown, T.H. (2020). "Thermal Management in Industrial Processes: Best Practices and Innovations", Chemical Engineering Progress, 116(8), 45-53.

5. Patel, N. & Suzuki, H. (2022). "Longevity and Performance of Refractory Materials in Extreme Environments", Materials Today: Proceedings, 50, 1876-1885.

6. Anderson, L.M. (2021). "Maintenance Strategies for High-Performance Laboratory Equipment", Lab Manager, 16(5), 22-28.

_1749118414004.webp)

_1745314183643.webp)

_1745829443030.webp)

_1745225223687.webp)