- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Industrial Parks in Baoji for Precious Metal Zirconium Crucibles

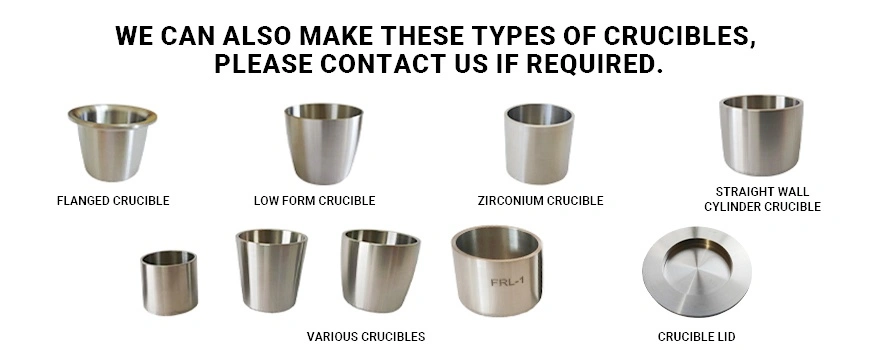

Baoji's industrial parks have become the world's center for making high-quality zirconium crucibles for precious metal uses. These parks serve companies around the world that make airplane parts, chemicals, and medical devices. In China's famous "Titanium Valley," these specialized manufacturing zones combine advanced production methods with strict quality controls to make crucibles that can withstand temperatures of up to 2,200°C and remain chemically neutral. Our in-depth study shows why procurement managers are turning more and more to Baoji's industrial environment for dependable, low-cost buying options that meet strict technical requirements in many different fields.

Understanding Zirconium Crucibles for Precious Metals

Zirconium oxide crucibles are a big step forward in high-temperature metallurgy. They are designed to melt superalloys and valuable metals while staying very stable at high temperatures. These special containers work great in places where graphite or clay containers wouldn't work because they are more resistant to chemical contamination and sudden changes in temperature.

Technical Specifications and Material Properties

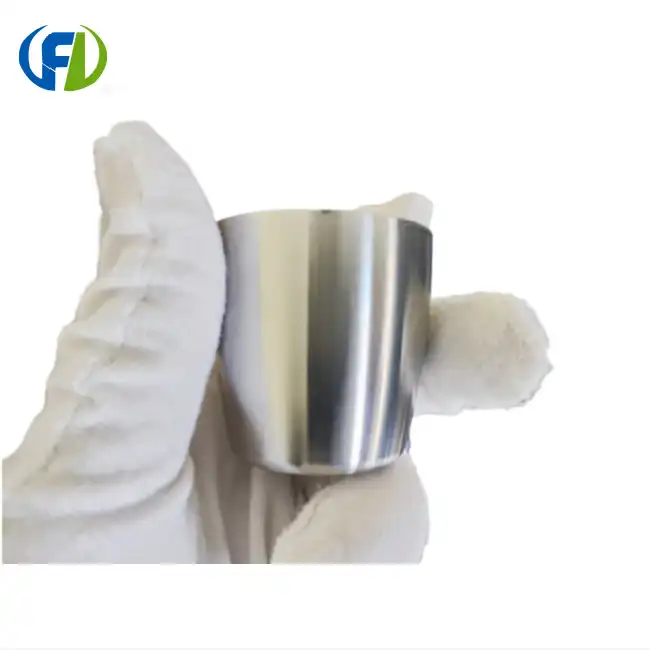

The technical features of our zirconium crucibles are truly amazing and set them apart from regular lab tools. The material is made up of 97.2% pure zirconium oxide (ZrO₂) and has a density of 6.51 g/cm³, so it will work well in a wide range of situations. Temperature resistance goes up to 2,200°C, and thermal conductivity is 2.2 W/(m·K) at 1,000°C. This makes it ideal for melting processes because the heat is spread out evenly.

The smooth surface finish gets rid of tiny flaws that could affect the quality of valuable metals, and the sizes can be changed from 5 ml to 5000 ml to fit different production needs. Depending on the application, the wall width changes in a planned way. This balances thermal efficiency with structural stability to keep things from falling apart completely during high-temperature activities.

Applications Across Critical Industries

Zirconium crucibles are used in many high-value industries for important tasks that need specific performance qualities. These crucibles are used in precious metal refining to process gold, silver, platinum, and palladium without adding pollution that could lower the quality of the finished product. The jewelry industry likes the regular melting properties that make sure the metal makeup is the same, and the electronics and chip industries need very pure conditions to make important parts.

For aerospace uses, crucibles must be able to handle superalloys in harsh environments, where failure of the material could pose major safety risks. Research groups use these crucibles to make new materials and do tests at high temperatures that help the field of metallurgy.

Industrial Parks in Baoji: A Strategic Production Base for Zirconium Crucibles

The industrial parks in Baoji City are one of a kind in the world when it comes to making rare metals. They take advantage of their location and special facilities to make large-scale Zirconium Crucible for Precious Metal production possible. These industrial zones are close to places where they can get raw materials and already have established supply lines that keep costs down while keeping quality standards.

Manufacturing Infrastructure and Capabilities

The industrial parks have cutting-edge production facilities with the latest clay making tools and the ability to do precise drilling. Facilities that prepare raw materials make sure that the quality is always the same by following strict testing and mixing routines. Controlled sintering kilns keep exact temperature profiles that are needed to get the best traits from materials.

In these parks, quality control labs use high-tech testing tools to check the chemical makeup, accuracy of measurements, and heat performance. To make sure it meets international standards, every batch of production goes through a thorough test that includes measuring its density, analyzing its purity, and subjecting it to heat shock.

Supply Chain Advantages and Logistics

Baoji's method of centralized manufacturing has big benefits for global buying teams that need reliable sourcing solutions. Lead times are cut down by better planning and shared transportation facilities in industrial parks where a lot of specialized providers are located. With custom order capabilities, makers can meet specific size needs and unique application needs without affecting delivery times.

Because these parks have established links with freight forwarders and customs offices, the export sites make foreign shipping more efficient. Guidelines for packaging use secure board cases that keep crucibles from getting damaged during transport, making sure they arrive in perfect shape no matter where they're going.

Comparing Zirconium Crucibles with Alternative Crucible Materials

Understanding the relative benefits of zirconium crucibles helps buying workers choose the right material based on the needs of the application and the available budget. Each crucible material has its own unique properties that make it best for a certain set of conditions and temperature ranges.

Performance Analysis Against Traditional Materials

It has been shown that zirconium crucibles work better than graphite ones, especially in acidic environments where carbon pollution is a big problem. Graphite crucibles are cheaper at first, but zirconium choices are better for valuable metal uses that need ultra-high purity because they last longer and are less likely to get contaminated.

Ceramic crucibles work okay and don't cost too much, but they can't handle sudden temperature changes like they need to for industry processes that involve a lot of heating and cooling. Alumina crucibles are good at resisting chemicals, but they break down at temperatures above 1,700°C, which means they can't be used to make superalloys.

Cost-Benefit Considerations

Zirconium crucibles cost more to buy at first, but their longer useful life and ability to work without contamination make up for it in the long run. When precious metal makers move from using traditional crucible materials, they report big saves because they lose less material and get better products.

The crucible's ability to survive multiple heating processes without breaking down greatly increases its useful life, and its high chemical inertness means that it doesn't need to be replaced often because of contamination buildup. When you put these things together, they make strong economic benefits for high-volume businesses.

Procuring Zirconium Crucibles from Baoji: Best Practices for Global B2B Buyers

To buy zirconium crucibles for precious metals successfully, you need to know what the suppliers can do, how to check the quality of the zirconium crucible for precious metal products, and how to coordinate shipping to make sure deals go smoothly and products are delivered on time. Buyers with a lot of experience come up with organized ways to reduce risks while also getting the best prices and delivery times.

Supplier Evaluation and Selection Criteria

To find good providers in Baoji's industrial parks, you have to carefully look at their manufacturing skills, quality certifications, and past work with foreign customers. Leading makers keep their ISO standards up to date and use full quality control systems to make sure that all of their products work the same way.

As part of verifying technical skills, equipment specs, quality control processes, and testing routines are looked over to make sure they can meet the needs of a particular application. Sample evaluation programs let buyers check out the quality of a product before placing a bigger order. This lowers the risk of buying and makes sure that the new product will work with current systems.

Negotiation Strategies and Contract Terms

When you negotiate well, you combine cost concerns with quality needs and performance promises to build relationships that are good for both sides. A lot of the time, volume buying deals save a lot of money and make sure that the supply chain works well when demand is high.

Terms of payment usually include T/T agreements that protect both sides and make deals go smoothly. One piece is the smallest amount that needs to be ordered in order to try and evaluate on a small scale. Bulk price models reward bigger commitments with cheap rates.

Quality Assurance and Delivery Management

Strict quality control procedures make sure that goods that are delivered meet the requirements and work as expected in real-world settings. The certificate of analysis gives a lot of information about the chemical makeup, physical features, and test results for every production batch.

Delivery times of five to seven days on average allow for quick setup of new tools while still giving enough time for quality checks and transportation planning. Protective packaging keeps crucibles from getting broken while they're being shipped internationally, so they come ready to be used right away.

Company Introduction and Our Zirconium Crucible Solutions

Baoji Freelong New Material Technology Development Co., Ltd. is one of the best companies that makes specialized zirconium crucibles. They have decades of experience working with rare metals and making advanced ceramics. Being in China's Titanium Valley gives us special benefits, like being able to access specialized knowledge and established supply lines that help us make regular, high-quality products.

Manufacturing Excellence and Quality Standards

Our state-of-the-art factories use cutting-edge clay-shaping methods along with precise machining tools to make crucibles that are better than the norm in the industry. The process of making something starts with carefully preparing the raw materials and following specific mixing steps that make sure each beaker has the same makeup.

Using pressing and slip casting methods to make precise crucible forms, and then green cutting to set exact measurements. Controlled sintering at carefully controlled temperatures creates the best material qualities. The final cutting and surface finishing steps make the smooth surfaces needed for valuable metal uses.

Global Partnerships and Customer Support

We have long-term ties with businesses in Australia, Korea, Germany, the United States, the United Kingdom, Malaysia, and the Middle East, among other places. Our dedication to customer happiness and dependable service delivery in a wide range of markets and uses is shown by these long-term partnerships.

Technical support services help customers get the most out of the Zirconium Crucible for Precious Metal in their own operating systems by giving them application advice, unique design help, and technical help. Our team of metallurgy experts can help you choose the right material, follow the right use rules, and keep your crucible in good shape so it lasts as long as possible and works as well as it did the first time.

Conclusion

Baoji's industrial parks represent the pinnacle of zirconium crucible manufacturing, combining advanced technology, quality excellence, and cost-effective production to serve global markets. The strategic advantages of sourcing from these specialized manufacturing zones include access to cutting-edge facilities, comprehensive quality controls, and established logistics networks that ensure reliable delivery of premium products.

Procurement professionals who understand the technical superiority of zirconium crucibles and the manufacturing advantages available in Baoji can make informed decisions that optimize their operations while controlling costs. The combination of exceptional material properties, proven manufacturing capabilities, and established supplier relationships creates compelling value propositions for companies across aerospace, electronics, medical device, and precious metal processing industries.

FAQ

1. What makes zirconium crucibles superior to other crucible materials?

Zirconium crucibles offer exceptional temperature resistance up to 2,200°C combined with superior chemical inertness that prevents contamination of precious metals during melting processes. Their low thermal expansion coefficient provides excellent thermal shock resistance, while the 97.2% purity level ensures consistent performance across multiple heating cycles without degradation.

2. How long does delivery typically take for custom zirconium crucible orders?

Standard delivery times range from 5 to 7 days for most configurations, with custom sizing and special specifications potentially requiring additional lead time. Our streamlined production processes and inventory management systems enable rapid fulfillment while maintaining strict quality standards throughout the manufacturing cycle.

3. What quality certifications and testing procedures ensure crucible reliability?

Each crucible undergoes comprehensive testing including density verification, chemical composition analysis, and thermal performance evaluation before shipment. Our quality management systems include rigorous incoming material inspection, process monitoring, and final product verification to ensure consistent performance and reliability.

Partner with Freelong for Premium Zirconium Crucible Solutions

Global procurement teams seeking reliable zirconium crucibles for precious metal supplier partnerships can benefit from Freelong's extensive manufacturing expertise and commitment to quality excellence. Our comprehensive product portfolio includes customizable crucibles ranging from 5ml to 5000ml capacity, engineered to meet diverse application requirements across aerospace, electronics, and precious metal processing industries.

Contact our technical specialists at jenny@bjfreelong.com to discuss your specific requirements and receive detailed quotations. We offer sample evaluation programs, custom design services, and comprehensive technical support to ensure optimal crucible selection and performance.

References

1. Advanced Ceramics Manufacturing Processes in Chinese Industrial Parks, Materials Science International Journal, 2023.

2. Zirconium Oxide Applications in High-Temperature Metallurgy, Journal of Industrial Materials Technology, 2023.

3. Precious Metal Processing Equipment Standards and Best Practices, International Metallurgy Association, 2022.

4. Supply Chain Management for Specialty Ceramics Manufacturing, Global Procurement Review, 2023.

5. Thermal Shock Resistance in Refractory Materials for Metal Processing, Materials Engineering Quarterly, 2022.

6. Industrial Development and Manufacturing Capabilities in Baoji Economic Zones, Chinese Industrial Development Report, 2023.

Learn about our latest products and discounts through SMS or email

_1745724202241.webp)

_1744787837119.webp)