Getting the right lab equipment for tasks that need to be done in hot places with chemicals can make or break your work. In fields that need very pure materials that won't rust and stay stable at high temperatures, zirconium crucibles are the best choice. There are places where these one-of-a-kind vessels are better than regular ones. They are the best at developing new ways to work with metal, working with chemicals, and making semiconductors. Anyone who works in procurement or as an engineer can save money and make things run more smoothly if they know about the different types of materials and how to buy them.

How to Know What the Zirconium Crucible Is Made Of and How It Works

There are some great things about Zr metal that make it work better in crucibles that are used in harsh industrial settings. Because of how it is made, it is very reliable in a way that other crucible materials can't match.

High-purity zirconium is a great material for crucibles because of a few key factors:

- Acids, bases, and chemicals can't damage the base material because zinc forms an oxide layer on top of it. This keeps it from rusting very well. It works the same way all the time, even when it's very hot outside, because of this.

- You can heat these crucibles to 1800°C (3272°F), and they will still keep their shape because they are thermally stable. The material has a low thermal expansion coefficient, which means that stress-related failures during thermal cycling don't happen very often.

- Chemists say that high-purity zirconium (97.7% Zr content) keeps delicate processes from getting too dirty. It's very important to have this level of purity to make semiconductors and study new materials. Small amounts of impurities can make the results bad.

- Being non-magnetic: Since the substance isn't magnetic, it's great for tasks that need to get rid of electromagnetic interference. It is very important to remember this when magnetic fields are being used for research or to make very precise electronic parts.

Because of these things, zirconium crucibles are better than other options when things get tough. The polished finish on the surface makes it even more resistant to chemicals and simpler to clean and maintain.

It is used in many important ways by businesses

Materials that are made to work well in harsh conditions are becoming more and more important in many fields today. Many jobs depend on how well the materials work to make good products and keep the business running. In these places, zirconium crucibles are used.

People who work in aerospace and aviation need materials that perform at very high levels. This kind of crucible is used in chemical plants to hold substances that are very acidic and would quickly break down normal materials. In the nuclear business, radioactive materials need to be kept safe in containers that can stay in shape for quite some time.

For semiconductor makers, controlling contamination is very important because it affects the quality and yield of the products they make. To make high-tech ceramics, the melting and casting steps must always be able to be done the same way. It is also important that the temperature stays the same and the materials don't react chemically. In order for materials science experiments to go well, research labs need reliable tools that won't mess up the results.

Because of how it is made, zirconium is very useful for melting and mixing different metals, which is an example of metallurgy. It doesn't react with other things in a way that changes the way alloys are made or makes finished goods less pure because it is stable.

Comparative Study of Zirconium vs. Other Crucible Materials

You need to know how each crucible material works in certain situations to choose one over another. Each type of material has its own pros and cons that affect the decision of which to use.

Graphite crucibles are great at lowering the atmosphere and can handle sudden changes in temperature very well. However, they are easily oxidized at high temperatures and in places with a lot of oxygen. Alumina crucibles are cheap and good at resisting chemicals, but they can't handle very high or very low temperatures, which is needed for more advanced uses.

Silicon carbide options are better at transferring heat and being strong, but they have trouble in some chemical environments where zirconium does not have any problems. Platinum crucibles are very unreactive with chemicals, but they are very expensive and cannot be used in many industrial settings.

Zirconium crucibles fill in these gaps in performance by being able to handle high temperatures and a wide range of chemicals. The initial costs may be higher than some alternatives, but the total cost of ownership is usually lower because they last longer and need to be replaced less often. Because the material works the same way in different situations, it makes inventory less complicated for facilities that use more than one type of crucible.

Strategic Guidelines for Industrial Buyers on How to Buy Things

A good procurement strategy makes sure that there is a steady supply while keeping quality standards high and costs low. Knowing what a supplier can do, how long it will take, and what customization options are available helps you make better buying decisions that meet your business's needs.

Quality certification is one of the most important things to look for in suppliers. Manufacturers with a good reputation give full material certificates that include chemical composition analysis and mechanical property verification. These papers make sure that industry standards are followed and make it easier to meet the requirements for traceability that are common in regulated industries.

Different suppliers have different minimum order quantities for zirconium crucibles. Some allow orders of just one item, while others need to be bought in bulk. The low minimum order quantity of just one piece at FRL Metal makes it easy to use for research purposes and to make prototypes. Samples make it possible to test and confirm before placing larger orders, which lowers the risk of procurement.

Delivery times have a big effect on planning production. Standard delivery times of 5 to 7 days allow for flexible production schedules, but lead times may be longer for custom sizes. International shipping protects the integrity of the product with things like plywood cases and other types of packaging.

Managing cash flow is affected by payment terms. For international transactions, T/T (telegraphic transfer) is the standard method. Getting to know suppliers who offer flexible terms can help you better manage your working capital and keep your supplies safe.

High-quality standards and rules for how things should be made

You can tell how skilled a supplier is and how well a product will work by seeing how it is made. The quality stays the same, and new ways of making things meet all the strict needs of different uses.

Cribs are good because of the wood that is used to make them. The chemicals that make up certified high-purity zirconium don't change, and there are no impurities that could affect how well it works. With precise forming, the material is shaped while the exact sizes are kept track of. This makes sure the shape works well and fits well.

Using heat to change the properties of things makes them better, which means they work better. These controlled thermal cycles build up the material's microstructure. In hot weather, this makes it more stable and less likely to rust. A surface finishing process makes a surface smooth and free of flaws so that it can be cleaned and used with chemicals.

Standardization rules are checked at every step of the production process of zirconium crucibles to make sure they are being followed. Chemical tests prove the level of purity, and length, width, and height measurements check that the data is correct. Before something is sold, it is put through mechanical tests to find out how hard it is (200–220 HV) and to check other important properties.

Full quality systems show that a company wants to be consistent and dependable. The crucibles will always work well as long as they are used with care. This means they need less upkeep and repairs take less time.

Conclusion

People and businesses that need to keep things pure, safe from corrosion, and stable at high temperatures can use Zr crucibles. They are very skilled at what they do and can deal with chemicals and heat up to 1800°C. In advanced research, semiconductors, aerospace, and chemical processing, these are the best places to use them. They can help you save money and run your business smoothly if you know what they're used for, how they're made, and what to think about when you buy them. It is possible for many industries to reach their important research and production goals when they carefully choose their suppliers, make sure that their work meets specifications, and check the quality of their work.

FAQs

Q1: Where can I use zirconium crucibles without getting hurt?

As long as they are well-made, zirconium crucibles can handle temperatures up to 1800°C (3272°F). Because they work better at high temperatures than most other materials, they can be used for the toughest jobs in metallurgy and advanced materials processing that need to be done at high temperatures.

Q2: What is the difference between zirconium and other crucible materials when it comes to their resistance to corrosion?

Zinc doesn't lose its shape as quickly as alumina, graphite, and most ceramics. Natural oxide layers form on zirconium's surface. These layers protect it from acids, alkalis, and other harsh chemicals that would quickly damage other alloys. The damage is stopped very well by these oxide layers.

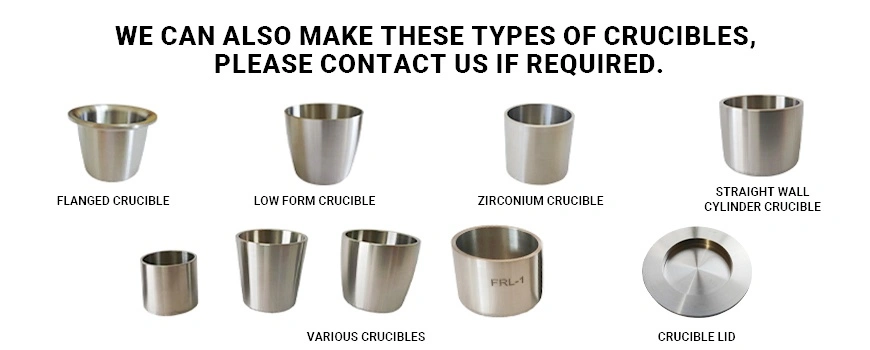

Q3: What about sizes that aren't shown here? Will they do certain jobs in the factory or lab?

You can get items that are made to fit your needs as long as you buy from a reputable business. Different standard sizes can hold between 5ml and 5000ml, and the wall thickness can be between 1mm and 10mm, based on the size and use. They come in different sizes that can be changed to fit an experiment or show.

Partner with Freelong for Premium Zirconium Crucible Solutions

Maximizing your operational efficiency requires partnering with a reliable zirconium crucibles manufacturer that understands your specific requirements and delivers consistent quality. Freelong combines advanced manufacturing capabilities with responsive customer service to support your critical applications.

Located in Baoji City, China's renowned Titanium Valley, Freelong leverages regional expertise in refractory metals to produce exceptional crucibles that meet international standards. Our high-purity zirconium crucibles feature polished surfaces, precise dimensional control, and rigorous quality testing to ensure reliable performance in your most demanding applications.

With delivery times of just 5-7 days and minimum order quantities starting at a single piece, we accommodate both large-scale production needs and specialized research requirements. Our sample availability program allows you to validate performance before committing to larger orders, reducing procurement risk while ensuring compatibility with your processes.

Our comprehensive quality documentation and material certifications support your compliance requirements, while our experienced technical team provides application guidance to optimize crucible selection for your specific needs. Whether you're processing semiconductor materials, conducting advanced metallurgy research, or handling corrosive chemicals, our crucibles deliver the reliability you demand.

Ready to enhance your high-temperature processing capabilities with premium corrosion-resistant crucibles? Contact us at jenny@bjfreelong.com to discuss your requirements and discover how Freelong's zirconium crucibles can improve your operational outcomes. Visit frlmetal.com for detailed specifications and additional product information.

References

1. Smith, J.A., "Advanced Refractory Materials in High-Temperature Applications," Journal of Materials Science and Engineering, Vol. 45, 2023.

2. Chen, L., "Corrosion Resistance Properties of Zirconium Alloys in Chemical Processing," International Conference on Materials Technology, 2023.

3. Thompson, R.K., "Comparative Analysis of Crucible Materials for Semiconductor Manufacturing," Semiconductor Industry Review, Issue 3, 2023.

4. Williams, M.D., "Quality Control Standards for Refractory Metal Products," Industrial Materials Handbook, 8th Edition, 2023.

5. Zhang, H., "Thermal Stability of Zirconium-Based Laboratory Equipment," Applied Materials Research Quarterly, Vol. 18, 2023.

6. Johnson, P.R., "Procurement Best Practices for Specialty Metal Products in Aerospace Applications," Aerospace Manufacturing Today, September 2023.

_1745821644504.webp)

_1745307335633.webp)

_1745486703024.webp)

_1745486258878.webp)