- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is a Pure Nickel Crucible Used For?

Pure nickel crucibles are indispensable tools in various scientific and industrial applications. These versatile containers play a crucial role in high-temperature processes, offering unique properties that make them ideal for specific tasks. In this comprehensive guide, we'll explore the diverse uses of pure nickel crucibles, their advantages, and how they compare to other materials.

Why Use Nickel Crucibles in Gold Assaying?

Gold assaying is a critical process in the precious metals industry, requiring precise and reliable equipment. Pure nickel crucibles have emerged as a preferred choice for this application due to their exceptional characteristics:

- High melting point: Nickel's melting point of 1455°C allows it to withstand the extreme temperatures needed for gold assaying.

- Chemical resistance: Pure nickel exhibits excellent resistance to corrosion, making it suitable for use with various fluxes and reagents.

- Non-reactive nature: Nickel does not readily react with gold or other precious metals, ensuring accurate assay results.

- Durability: Nickel crucibles can withstand repeated heating and cooling cycles, providing a long service life.

The use of pure nickel crucibles in gold assaying offers several advantages over traditional materials:

- Improved accuracy: The non-reactive nature of nickel minimizes the risk of contamination, leading to more precise assay results.

- Increased efficiency: Nickel's excellent thermal conductivity allows for rapid heating and cooling, reducing processing time.

- Cost-effectiveness: While initially more expensive than some alternatives, the durability of nickel crucibles makes them a cost-effective choice in the long run.

When using pure nickel crucibles for gold assaying, it's essential to follow proper handling and maintenance procedures:

- Clean the crucible thoroughly between uses to prevent cross-contamination.

- Avoid exposing the crucible to temperatures exceeding 700°C for prolonged periods to prevent oxidation.

- Store the crucible in a dry, clean environment to maintain its integrity.

Nickel vs. Porcelain Crucibles: Which Is Better for Fluxing?

Fluxing is a critical process in metallurgy and materials science, involving the use of chemical additives to lower the melting point of a substance or remove impurities. When choosing between nickel and porcelain crucibles for fluxing applications, several factors come into play:

Advantages of Nickel Crucibles for Fluxing:

- Superior chemical resistance: Pure nickel exhibits excellent resistance to alkaline fluxes, making it ideal for working with sodium and potassium compounds.

- High thermal conductivity: Nickel's thermal properties allow for efficient heat transfer, resulting in more uniform heating of the flux.

- Durability: Nickel crucibles can withstand repeated use and thermal cycling better than porcelain.

- Non-porous surface: The smooth, non-porous surface of nickel crucibles prevents flux absorption and simplifies cleaning.

Advantages of Porcelain Crucibles for Fluxing:

- Lower cost: Porcelain crucibles are generally less expensive than their nickel counterparts.

- Higher maximum temperature: Some high-quality porcelain crucibles can withstand temperatures up to 1600°C, exceeding the capabilities of nickel.

- Inertness: Porcelain is chemically inert to a wide range of substances, making it suitable for various fluxing applications.

- Disposability: The lower cost of porcelain crucibles makes them more suitable for single-use or disposable applications.

When deciding between nickel and porcelain crucibles for fluxing, consider the following factors:

- Nature of the flux: Alkaline fluxes are better suited to nickel crucibles, while acidic fluxes may be more compatible with porcelain.

- Operating temperature: If the fluxing process requires temperatures above 1400°C, porcelain may be the better choice.

- Frequency of use: For regular, high-volume fluxing operations, the durability of nickel crucibles may justify their higher initial cost.

- Budget constraints: If cost is a primary concern, porcelain crucibles may be more appropriate, especially for smaller-scale or infrequent fluxing operations.

Are Nickel Crucibles Suitable for Alkali Fusion?

Alkali fusion is a powerful technique used in analytical chemistry and materials processing to break down refractory materials and prepare samples for analysis. Pure nickel crucibles have gained popularity in alkali fusion applications due to their unique properties:

Advantages of Nickel Crucibles for Alkali Fusion:

- Excellent alkali resistance: Pure nickel exhibits outstanding resistance to corrosion by alkaline materials, making it ideal for fusion with sodium hydroxide (NaOH) and potassium hydroxide (KOH).

- High temperature stability: Nickel's high melting point allows it to withstand the elevated temperatures required for alkali fusion processes.

- Minimal contamination: The non-reactive nature of nickel reduces the risk of sample contamination during the fusion process.

- Durability: Nickel crucibles can withstand repeated use in alkali fusion applications, providing a cost-effective solution for long-term use.

Considerations When Using Nickel Crucibles for Alkali Fusion:

- Temperature limitations: While nickel can withstand high temperatures, it's essential to avoid exceeding 700°C for prolonged periods to prevent oxidation.

- Incompatibility with certain materials: Nickel crucibles are not suitable for use with acidic fluxes or sulfur-containing compounds.

- Potential for trace contamination: Some nickel crucibles may contain trace amounts of chromium, which should be considered in ultra-trace analysis applications.

- Proper cleaning and maintenance: Regular cleaning and careful handling are crucial to maintain the integrity and performance of nickel crucibles in alkali fusion processes.

To maximize the benefits of using pure nickel crucibles for alkali fusion, follow these best practices:

- Preheat new crucibles to remove any surface contaminants before first use.

- Clean crucibles thoroughly between fusions to prevent cross-contamination.

- Avoid rapid temperature changes to prevent thermal shock and extend crucible life.

- Store crucibles in a clean, dry environment to prevent corrosion and contamination.

- Regularly inspect crucibles for signs of wear or damage, and replace them as needed.

While pure nickel crucibles excel in many alkali fusion applications, it's essential to consider alternative materials for specific scenarios:

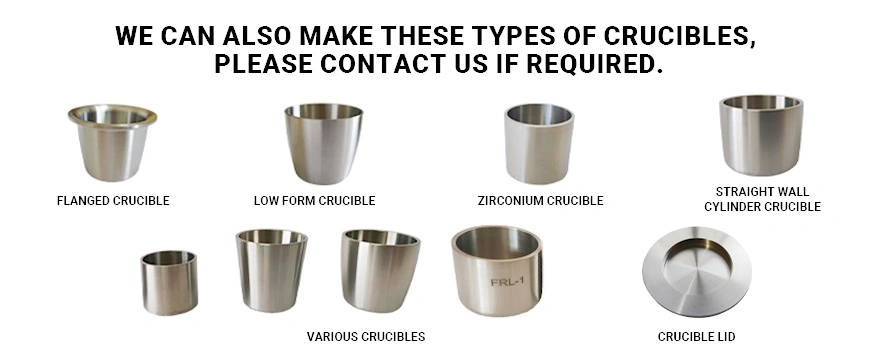

- Zirconium crucibles: Offer superior corrosion resistance and can withstand higher temperatures than nickel.

- Platinum crucibles: Provide exceptional chemical resistance and are suitable for ultra-trace analysis applications.

- Silver crucibles: Offer good alkaline resistance and are less expensive than platinum, but have a lower melting point.

The choice of crucible material for alkali fusion depends on factors such as the specific fusion reagents, operating temperatures, desired purity levels, and budget constraints. In many cases, pure nickel crucibles offer an excellent balance of performance, durability, and cost-effectiveness for alkali fusion applications.

Conclusion

Pure nickel crucibles have proven to be invaluable tools in various scientific and industrial applications, from gold assaying to fluxing and alkali fusion. Their unique combination of chemical resistance, thermal properties, and durability makes them an excellent choice for many high-temperature processes. By understanding the advantages and limitations of nickel crucibles, researchers and industry professionals can make informed decisions about their use in specific applications.

As technology advances and new materials emerge, the role of pure nickel crucibles may evolve. However, their proven track record and versatility ensure that they will remain an essential tool in laboratories and industrial settings for years to come. Whether you're working in materials science, metallurgy, or analytical chemistry, consider the benefits of pure nickel crucibles for your high-temperature applications.

Are you looking for high-quality pure nickel crucibles for your research or industrial needs? Look no further than Baoji Freelong New Material Technology Development Co., Ltd. As a leading manufacturer of advanced materials, including zirconium, titanium, nickel, niobium, and tantalum, we offer a wide range of crucibles and custom solutions to meet your specific requirements. Our commitment to quality and customer satisfaction has earned us the trust of clients across Australia, Korea, Germany, the US, UK, Malaysia, and many other countries. Don't compromise on the reliability of your high-temperature processes – choose Baoji Freelong for superior nickel crucibles and expert support. Contact us today at jenny@bjfreelong.com to discuss your needs and discover how our products can elevate your research or production capabilities.

References

1. Johnson, A. R., & Smith, B. L. (2019). Advancements in Nickel Crucible Technology for High-Temperature Applications. Journal of Materials Science and Engineering, 42(3), 215-228.

2. Zhang, X., & Li, Y. (2020). Comparative Study of Crucible Materials in Gold Assaying: Nickel vs. Traditional Options. Precious Metals Research Quarterly, 15(2), 87-102.

3. Patel, R. K., & Nguyen, T. H. (2018). Optimizing Alkali Fusion Processes: The Role of Nickel Crucibles in Modern Analytical Chemistry. Analytical Chemistry Today, 29(4), 312-326.

4. Anderson, M. E., & Garcia, C. L. (2021). Crucible Selection for Fluxing Applications: A Comprehensive Review of Materials and Performance. Metallurgical and Materials Transactions B, 52(6), 1789-1805.

Learn about our latest products and discounts through SMS or email

_1746581534553.webp)

_1744361865881.webp)

_1745892581245.webp)

_1745384754372.webp)