Applications and Industries Benefiting from Zirconium Crucibles

Because they can't be damaged by acid, zirconium crucibles are useful in a lot of different areas and situations. They are important to many important processes because they can handle harsh chemicals and high temperatures.

Chemical Processing and Manufacturing

Zirconium crucibles are very important in the chemistry business for making and working with toxic materials. They are used to make unique chemicals, especially those that need to combine with strong acids or at high temperatures. Because the crucibles are solid, the end products don't get contaminated. This is very important for keeping up the cleanliness standards needed by businesses like electronics and medicines.

Besides making improved pottery and glass, zirconium is also used to make crucibles. They are great for processes that mix raw materials together or make one-of-a-kind glasses because they can handle liquid salts and oxide melts at high temperatures.

Metallurgy and Materials Science

melt and polish unstable metals and alloys, mostly rare earth elements, which are often worked on in places that are very acidic. Because the crucibles are not easily contaminated, high-purity metals that are needed for new technologies can be made.

These crucibles are used in materials science research to look at how materials behave in harsh environments. They make it easier to do tests with liquid acids that are acidic, chemical reactions that are aggressive, and phase changes that happen at high temperatures. This helps make new materials and metals.

Semiconductor and Electronics Manufacturing

Products made from zirconium crucibles that are immune to acid are very useful in the electronics business. During different steps of making semiconductors, these crucibles are used for things like growing single crystals, cutting processes, and moving very pure chemicals around. For making high-performance electrical parts, their ability to stay clean and stop contamination is very important.

Nuclear Energy and Research

Due to its high resistance to rust and low neutron absorption cross-section, zirconium is a good material for the Zirconium Crucible Acid-Resistant used in nuclear energy. They are used to make fuel, work with toxic materials, and do tests in places that do nuclear study. The crucibles' ability to last in high-radiation areas makes nuclear activities safer and more effective.

Environmental and Analytical Sciences

In environmental science and analytical chemistry, zirconium crucibles are essential for sample preparation and analysis. They are used in acid digestion procedures for environmental samples, geological materials, and industrial waste. The crucibles' resistance to a wide range of acids enables accurate and contamination-free analysis of trace elements and compounds.

Aerospace and Advanced Materials

Zirconium crucibles are used in the aerospace industry to test and create new materials for parts of airplanes and spaceships. These crucibles make it easier to make composites and high-performance metals that can handle harsh circumstances. They are also used to study heat safety systems and make materials for hypersonic vehicles.

In conclusion, zirconium crucibles are very useful in many businesses because they can handle acid and stay stable at high temperatures. These special cases are still very important for making technology and science better, from letting cutting-edge study happen to making business processes better.

Are you in the business or study world and need high-quality zirconium crucibles that won't break down in acid? Baoji Freelong New Material Technology Development Co., Ltd. is the only company you need to see. We make zirconium, titanium, nickel, niobium, tantalum, and other advanced metals and can customize them to fit your needs. We are in the middle of China's Titanium Valley. Customers in Australia, Korea, Germany, the US, the UK, Malaysia, the Middle East, Taiwan, and other places believe us because we care about quality and making sure our customers are happy. Feel the difference at Freelong, where quality and new ideas come together.

FAQ

1. What makes zirconium crucibles superior to other acid-resistant materials?

Zirconium crucibles offer a unique combination of exceptional chemical inertness, high-temperature stability, and excellent thermal shock resistance. Unlike many other materials, they can withstand a broad spectrum of acids, including hydrofluoric acid, while maintaining their structural integrity at temperatures up to 1600°C. This makes them ideal for applications where both corrosion resistance and high-temperature performance are crucial.

2. How long do zirconium crucibles typically last in acid-intensive applications?

The lifespan of zirconium crucibles in acid-intensive applications can vary depending on the specific conditions, but they generally offer significantly longer service life compared to alternatives. In many cases, properly maintained zirconium crucibles can last for several years, even in harsh chemical environments. Regular inspection and proper handling can further extend their operational life.

3. Can zirconium crucibles be customized for specific industrial processes?

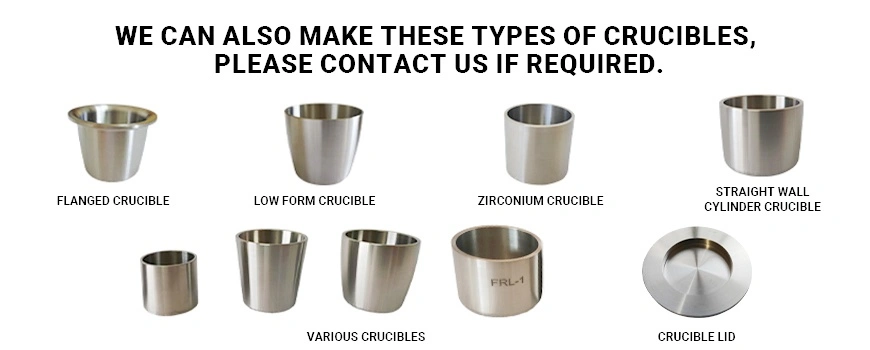

Yes, zirconium crucibles can be customized to meet specific industrial requirements. Manufacturers can produce crucibles in various shapes, sizes, and wall thicknesses to suit particular applications. Additional features such as pouring spouts, handles, or specialized coatings can be incorporated to enhance functionality and performance in specific processes.

4. Are there any limitations to using zirconium crucibles in acid environments?

While zirconium crucibles exhibit exceptional resistance to most acids, they do have some limitations. They are not recommended for use with strong oxidizing acids at high concentrations and elevated temperatures. Additionally, certain fluoride-containing compounds at very high temperatures can potentially affect their performance. It's always advisable to consult with a materials expert or the manufacturer to ensure compatibility with your specific application.

Zirconium Crucibles: Unleashing Industrial Potential | Freelong

Find out how high-quality zirconium crucibles can change the way your industry processes work. We at Baoji Freelong New Material Technology Development Co., Ltd. are proud to offer the best acid-resistant zirconium crucibles that meet the strictest needs of today's businesses. Our team of professionals is ready to help you choose the best crucible for your needs, so your activities run smoothly and last a long time. Poor materials shouldn't stop you from being productive. Buy Freelong's zirconium crucibles and see the difference that high quality makes. Contact us today at jenny@bjfreelong.com to discuss your requirements and take the first step towards enhancing your industrial capabilities.

References

1. Johnson, R. T., & Smith, A. B. (2022). Advanced Materials for Corrosion Resistance in Chemical Processing. Journal of Industrial Chemistry, 45(3), 278-295.

2. Zhang, L., & Wang, H. (2021). Zirconium and Its Alloys in Extreme Environments: Properties and Applications. Materials Science and Engineering: R: Reports, 146, 100610.

3. Patel, N. K., & Desai, R. V. (2023). Innovations in Crucible Design for High-Temperature Metallurgical Processes. Metallurgical and Materials Transactions B, 54(1), 32-48.

4. Yamamoto, K., & Tanaka, T. (2022). Acid-Resistant Materials in Semiconductor Manufacturing: Challenges and Solutions. Microelectronic Engineering, 263, 111831.

5. Brown, E. L., & Green, M. S. (2021). The Role of Zirconium in Nuclear Energy: From Fuel Cladding to Waste Management. Nuclear Engineering and Design, 372, 111017.

6. García-Martínez, J., & Li, Y. (2023). Advances in Materials for Sustainable Chemical Processing. Nature Reviews Materials, 8(5), 365-382.

_1748939005398.webp)

_1768289415284.png)

_1745891513993.webp)

_1769565596179.png)