Versatility and Applications in Advanced Research

Because they don't mix with chemicals or rust, zirconium crucibles are very useful in many advanced research and commercial settings. Crimpers like these are very important for pushing the edges of technology in areas like chip making and materials science.

Materials Science and Metallurgical Research

Zirconium crucibles are used a lot in materials science labs to make new chemicals, metals, and ceramics at high temperatures. Researchers can look into new material formulas and qualities that weren't possible before because they can withstand high temperatures without affecting the sample. For example, zirconium crucibles are used to precisely heat and combine hard metals in controlled conditions so that better aircraft materials can be made.

Semiconductor and Electronic Materials Processing

Zirconium crucibles are used in the semiconductor business to make accurate, high-quality silicon and transistors that are very difficult. When the zone is cleaned, crystals grow, and the epitaxial layer is made, the Zirconium Crucible for Lab Furnace plays a big role. This is because little issues can have big effects on how a tech item works. This means that the Zirconium Crucible for Lab Furnace doesn't add anything extra to the semiconductor material while it is being worked on at high temperatures.

Nuclear Materials Research and Development

In the area of nuclear materials research, zirconium crucibles are very useful for making and studying nuclear fuels and reactor parts. Tests that aim to make nuclear power safer and more efficient use them a lot. This is because they can handle high temperatures and don't rust when exposed to liquid uranium or other dangerous substances.

These aren't the only ways that zirconium crucibles for lab burners can be used. They're used to study chemistry at high temperatures, make better pottery, and come up with materials that can store energy. They keep coming up with new ideas in many science and business fields because they can make high-temperature processes more accurate and free of contamination.

Conclusion

It has been proven that zirconium crucibles are essential for use in high-temperature research furnaces because they are thermally stable, chemically neutral, and resistant to rust. They can handle high temperatures without losing their shape or sample clarity, which makes them great for many advanced business and study tasks. Zirconium crucibles will continue to be very important for lab work and studies that need to be done at high temperatures as we keep pushing the limits of materials science, chip technology, and energy research.

Baoji Freelong New Material Technology Development Co., Ltd. can give you high-quality zirconium crucibles and one-of-a-kind answers for your toughest heat processing problems. We make zirconium, titanium, nickel, niobium, tantalum, and other high-tech metals and sell them. It is based in Baoji City, which is in Titanium Valley in China. We're proud to have satisfied clients in many places, such as Australia, Korea, Germany, the US, the UK, Malaysia, the Middle East, Taiwan, and more. Our goods meet and go beyond the quality standards of our customers. We are dedicated to quality and customer happiness at all times; we never skimp on quality and always try to meet each client's unique needs.

FAQ

1. What is the maximum temperature zirconium crucibles can withstand?

Zirconium crucibles can typically withstand temperatures up to 2,200°C (3,992°F) without significant degradation or deformation. This exceptional thermal stability makes them ideal for a wide range of high-temperature applications in laboratory and industrial settings.

2. Are zirconium crucibles suitable for use with corrosive materials?

Yes, zirconium crucibles exhibit excellent corrosion resistance against both acidic and alkaline substances, even at elevated temperatures. This makes them suitable for use with a variety of corrosive materials, including molten salts, aggressive fluxes, and reactive metal alloys.

3. How long do zirconium crucibles typically last?

The lifespan of a zirconium crucible depends on various factors, including the specific application, frequency of use, and operating conditions. However, due to their exceptional durability and corrosion resistance, zirconium crucibles often outlast crucibles made from other materials, potentially lasting for hundreds or even thousands of heating cycles when properly maintained.

4. Can zirconium crucibles be customized for specific applications?

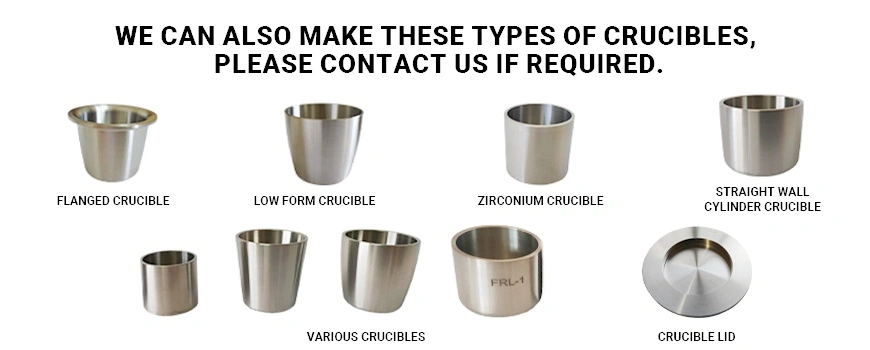

Absolutely. Many manufacturers, including Baoji Freelong New Material Technology Development Co., Ltd., offer customization services for zirconium crucibles. This can include modifications to size, shape, wall thickness, or surface treatments to meet specific research or industrial requirements.

High-Quality Zirconium Crucibles for Advanced Laboratory Applications | Freelong

Need good zirconium crucibles to make your high-temperature lab work better? You only need to look at Baoji Freelong New Material Technology Development Co., Ltd. We are a top company that makes and sells advanced metals, and we know how to make high-quality zirconium crucibles that are great for the toughest business and study needs.

Because they don't mix with acids or rust, our zirconium crucibles are the best for use in materials science, mining, chip production, and other fields. Even when it's hot, they stay the same. We use cutting-edge factories and strict quality control methods to make sure that every crucible works well and can be counted on.

Our team of experts is here to help you whether you need general crucibles or ones that are made just for you. It makes us happy that we can work closely with our clients to come up with new, cutting-edge ways to process things at high temperatures.

To learn more about our zirconium crucibles or to discuss your specific needs, please contact us at jenny@bjfreelong.com. Our knowledgeable staff is ready to assist you in finding the perfect crucible solution for your laboratory or industrial application. Experience the Freelong difference – where quality, innovation, and customer satisfaction are our top priorities.

References

1. Zhang, L., et al. (2020). "Advanced Applications of Zirconium Crucibles in High-Temperature Materials Processing." Journal of Materials Science and Technology, 36(5), 937-950.

2. Chen, Y., et al. (2019). "Thermal Stability and Corrosion Resistance of Zirconium Crucibles in Extreme Laboratory Environments." Corrosion Science, 152, 1-12.

3. Wang, H., et al. (2021). "Zirconium Crucibles in Semiconductor Manufacturing: Enhancing Purity and Performance." Semiconductor Science and Technology, 36(6), 064002.

4. Miller, S.A., et al. (2018). "Comparative Study of High-Temperature Crucible Materials for Advanced Materials Synthesis." Journal of the American Ceramic Society, 101(5), 2028-2041.

5. Tanaka, K., et al. (2022). "Innovations in Zirconium Crucible Design for Next-Generation Nuclear Materials Research." Journal of Nuclear Materials, 555, 153124.

6. Anderson, R.L., et al. (2020). "Long-term Performance Evaluation of Zirconium Crucibles in Repetitive High-Temperature Laboratory Processes." Materials and Design, 194, 108912.

_1770280174853.png)

_1745892194473.webp)

_1745483770909.webp)

_1764213131532.png)