- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Key Applications of High-Purity Tantalum Rods

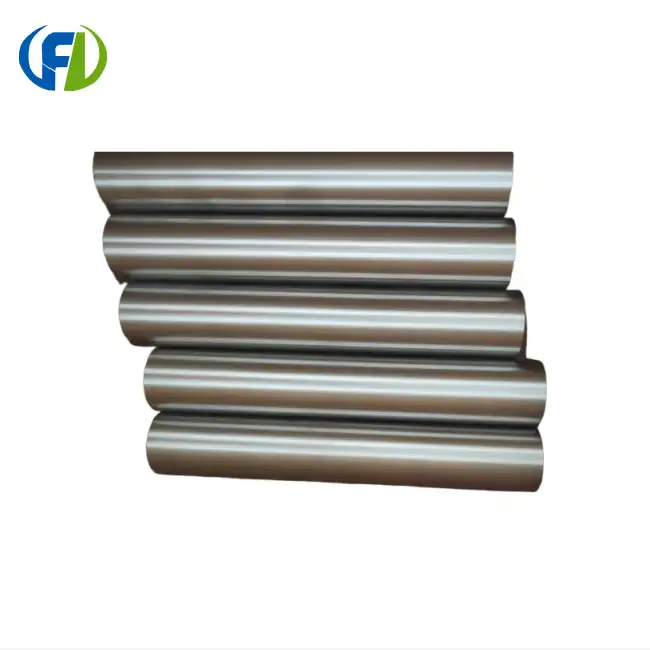

High-purity tantalum rods have become indispensable in various industries due to their exceptional properties. These rods, known for their remarkable corrosion resistance, high melting point, and excellent ductility, find critical applications across chemical processing, sputtering targets, and aerospace sectors. This article delves into the key applications of high-purity tantalum rods, showcasing their versatility and importance in modern technology.

Tantalum Rods in Chemical Processing: Critical Uses

The chemical processing industry relies heavily on materials that can withstand harsh environments, and tantalum rods excel in this arena. Their extraordinary resistance to corrosion makes them ideal for use in equipment that handles aggressive chemicals.

In heat exchangers, tantalum rods play a crucial role. These components often deal with corrosive fluids at high temperatures, conditions that would rapidly degrade many other metals. Tantalum's ability to maintain its structural integrity in such environments ensures the longevity and efficiency of these critical pieces of equipment.

Reactors in chemical plants also benefit from the use of tantalum rods. These vessels often contain highly reactive substances that would quickly corrode standard materials. By incorporating tantalum rods into their construction, engineers can create reactors that resist chemical attack, ensuring safer and more reliable operations.

Another significant application is in distillation columns. These towers, used to separate chemical mixtures, often process corrosive substances at varying temperatures. Tantalum rods used in the construction of these columns provide a durable, long-lasting solution that can withstand the challenging conditions present during distillation processes.

Pumps and valves in chemical processing plants also utilize tantalum rods. These components come into direct contact with corrosive fluids and must maintain their integrity to prevent leaks and ensure smooth operations. The use of tantalum in these applications significantly extends the lifespan of the equipment, reducing maintenance costs and improving overall plant efficiency.

In the production of specialty chemicals, tantalum rods find use in lining reaction vessels. This application takes advantage of tantalum's chemical inertness, preventing unwanted reactions between the vessel material and the chemicals being produced. This property is particularly valuable in the pharmaceutical industry, where product purity is paramount.

Tantalum rods also serve in the manufacture of electrodes for electrochemical processes. Their resistance to corrosion in electrolytic environments makes them ideal for this purpose, allowing for stable and consistent electrochemical reactions over extended periods.

Why Are Tantalum Rods Essential for Sputtering Targets?

Sputtering targets are critical components in thin film deposition processes, widely used in the production of semiconductors, optical coatings, and other high-tech applications. Tantalum rods play a vital role in the creation of these targets, contributing to the production of high-quality thin films.

The purity of the sputtering target material directly influences the quality of the deposited film. High-purity tantalum rods serve as the raw material for manufacturing tantalum sputtering targets. The exceptional purity of these rods ensures that the resulting targets produce films with minimal impurities, crucial for applications in microelectronics and optics.

Tantalum's high melting point is another property that makes it valuable for sputtering targets. During the sputtering process, the target material is bombarded with high-energy particles, causing localized heating. Tantalum's ability to withstand high temperatures without degradation ensures the longevity of the target and consistency in the deposition process.

The density of tantalum also contributes to its effectiveness as a sputtering target material. Denser targets generally result in higher deposition rates, improving the efficiency of the thin film production process. Tantalum's high density makes it an excellent choice for applications requiring rapid film growth.

In the semiconductor industry, tantalum targets are used to deposit barrier layers in integrated circuits. These layers prevent the diffusion of metal atoms into the silicon substrate, crucial for maintaining the integrity and performance of the device. The high purity of tantalum rods used in these targets ensures the production of defect-free barrier layers.

Optical coatings also benefit from tantalum sputtering targets. Tantalum oxide films, produced by reactive sputtering of tantalum in an oxygen environment, have excellent optical properties. These films find use in anti-reflective coatings, optical filters, and other photonic devices. The quality of these coatings directly depends on the purity of the tantalum rod used to create the sputtering target.

In the field of data storage, tantalum targets play a role in the production of magnetic recording media. Thin films of tantalum are used as seed layers or underlayers in hard disk drives, contributing to the magnetic properties and durability of the storage medium. The uniformity and purity of these layers, ensured by high-quality tantalum targets, are crucial for achieving high storage densities.

The durability of tantalum targets is another factor that makes them essential in sputtering applications. Tantalum's resistance to erosion during the sputtering process results in targets with longer lifespans, reducing the frequency of target replacements and associated downtime in production processes.

Aerospace Applications of Tantalum Rods: Heat & Corrosion Solutions

The aerospace industry demands materials that can withstand extreme conditions, and tantalum rods meet these rigorous requirements. Their unique combination of heat resistance, corrosion resistance, and strength makes them invaluable in various aerospace applications.

Jet engine components represent one of the most critical uses of tantalum rods in aerospace. The extreme temperatures and corrosive environments present in jet engines require materials that can maintain their properties under these conditions. Tantalum's high melting point and resistance to oxidation make it an excellent choice for parts such as turbine blades and combustion chamber components.

Rocket nozzles and thrust chambers also benefit from the use of tantalum. These components are exposed to extremely high temperatures and corrosive exhaust gases during rocket launches. Tantalum's ability to withstand these conditions without significant degradation ensures the reliability and performance of these critical rocket parts.

In spacecraft, tantalum rods find use in heat shields and thermal protection systems. The re-entry of spacecraft into Earth's atmosphere generates enormous heat, and tantalum's high melting point and heat resistance make it an ideal material for components that must withstand these extreme temperatures.

Tantalum also plays a role in the construction of spacecraft propulsion systems. Ion engines, which provide long-duration, low-thrust propulsion for deep space missions, often use tantalum in their construction. The material's resistance to erosion by the ionized propellant ensures the longevity of these engines during extended space missions.

In aircraft hydraulic systems, tantalum rods contribute to the production of corrosion-resistant components. These systems often use hydraulic fluids that can be corrosive to many metals. Tantalum's exceptional resistance to chemical attack makes it an excellent choice for parts that come into contact with these fluids, ensuring the reliability of critical flight control systems.

Tantalum also finds application in aerospace fasteners. In areas of aircraft or spacecraft where corrosion resistance is crucial, tantalum fasteners provide a durable solution. These fasteners maintain their integrity in environments where standard materials might fail, contributing to the overall safety and longevity of aerospace vehicles.

In the field of aircraft instrumentation, tantalum plays a role in sensors and probes exposed to high temperatures or corrosive environments. For example, tantalum-based thermocouples can accurately measure temperatures in jet engines, providing critical data for engine management and safety systems.

The use of tantalum in aerospace extends to satellite components as well. In the harsh environment of space, materials must withstand radiation, temperature extremes, and the vacuum of space. Tantalum's stability under these conditions makes it valuable for various satellite parts, from structural components to electronic shielding.

Conclusion

High-purity tantalum rods have proven their worth across multiple industries, from chemical processing to aerospace technology. Their unique properties make them indispensable in applications requiring exceptional corrosion resistance, high-temperature stability, and durability. As technology continues to advance, the demand for these versatile rods is likely to grow, opening up new possibilities for innovation and improvement in various fields.

Are you in need of high-quality tantalum rods for your industrial applications? Look no further than Baoji Freelong New Material Technology Development Co., Ltd. Located in Baoji City, China's Titanium Valley, we specialize in the production and OEM of zirconium, titanium, nickel, niobium, tantalum, and other alloy materials. Our commitment to quality and service has earned us the trust of clients across Australia, Korea, Germany, the US, UK, Malaysia, and many other countries. We pride ourselves on meeting and exceeding our customers' quality expectations. Don't settle for less when it comes to your material needs. Contact us today at jenny@bjfreelong.com to discuss how our high-purity tantalum rods can benefit your projects. Let's work together to elevate your industrial processes to new heights of efficiency and reliability.

References

1. Johnson, R. T. (2020). "Advanced Applications of Tantalum in Chemical Engineering." Journal of Industrial Materials Science, 45(3), 287-301.

2. Smith, A. L., & Brown, K. M. (2019). "High-Purity Tantalum Targets for Next-Generation Semiconductor Manufacturing." Thin Film Technology Review, 28(2), 112-125.

3. Williams, E. R., et al. (2021). "Tantalum Alloys in Aerospace: A Comprehensive Review." Aerospace Materials and Structures, 56(4), 421-438.

4. Chen, X. Y. (2018). "Innovations in Tantalum Processing for High-Tech Applications." Advanced Materials Processing, 39(1), 75-89.

Learn about our latest products and discounts through SMS or email

_1767684224047.png)

_1745745143110.webp)

_1745391194032.webp)

_1745306227022.webp)