The choice of the correct crucible material is very important for safety and success when working with hard chemicals and poisonous materials. There is no better choice than zirconium crucibles if you need to work in an acidic area. They last a very long time and are very resistant to chemicals. The Zirconium Crucible Acid-Resistant technology works well even in the worst situations, so businesses can count on it. In this way, the process stays clean, and downtime is cut down, which saves money. Heavy acids, strong bases, and other harmful chemicals that break down regular materials quickly need to be put in these special tanks in places where they will be used.

Understanding the Science Behind Zirconium's Exceptional Acid Resistance

Understanding the Science Behind Zirconium's Superb Resistance to Acid

Because of how it is made and the protective metal layer that forms on top of it, zirconium can handle things that are acidic very well. Strong chemicals treat zirconium by making a thick, sticky oxide film that keeps other chemicals from attacking it. The crucible is safe as long as this passive layer is used because it fixes itself right away if it gets hurt.

Because of how its atoms are arranged, zirconium is biologically neutral. Even very strong acids can't break down zirconium because its electrons stay put and its metal bands are strong. There is at least 99.2% purity in our high-purity zirconium crucibles because they are made of Zr702 and Zr704 metals. Chemically, this means they are very solid and don't get messed up easily.

You can compare zirconium to clay crucibles, quartz, or graphite, but it lasts longer and is more stable. When it gets hot, quartz breaks and graphite turns black, but zirconium stays strong at a wide range of temperatures and doesn't chemically break down.

Key Performance Advantages of Acid-Resistant Zirconium Crucibles

Materials used in modern manufacturing processes need to be able to handle more difficult conditions while still staying the same size and performing the same way every time. The Zirconium Crucible Acid-Resistant is very valuable because it has many performance features that directly affect how efficiently operations run.

As a general rule, zirconium crucibles are great for tough jobs because:

- Chemical Resistance: It can handle hydrofluoric acid, aqua regia, and other strong acids that quickly break down other materials. It will last a lot longer than other options because of this.

- When heated and cooled quickly, it keeps its shape very well. It doesn't change shape at temperatures as high as 1600°C (2912°F).

- Very Good Mechanical Features: It's strong and flexible, so it doesn't break easily. When you push it together, it always works.

- Not very likely to get sick: Because the materials are so pure, they don't pick up many elements when they are handled. This is important for sensitive processes like research and production.

These traits of performance directly lead to practical benefits such as lower upkeep costs, higher product quality, and more reliable processes. Zirconium's ability to avoid pollution is especially useful for industries that work with high-value materials.

Strategic Material Selection: Comparing Crucible Options for Harsh Environments

You should carefully consider the process needs, chemical compatibility, and cost when picking the best crucible materials. When you compare how different materials work, you can make smart buying choices that help your business run more smoothly.

In a number of important ways, zirconium crucibles are better than standard options. Even though platinum crucibles are very resistant to chemicals, they are too expensive for many uses, so zirconium is often a better choice. Ceramic crucibles are cheap, but they don't have the chemical compatibility and strength to withstand temperature shock that are needed for working with strong acids.

Some important factors for crucible choosing are:

- Zirconium can stand up to a lot of different acids and their concentrations without breaking down or polluting it.

- Temperature Performance: The material you choose depends on the working temperatures, heating rates, and length of time you need the thermal cycle to work. Most materials don't change much when they get hot or cold.

- What I think about the economy: The cost of buying something, how long it lasts, how often it needs to be fixed, and the costs of downtime are all part of the total cost of ownership.

People who work in procurement can get more done when they work with skilled manufacturers who know how to meet the needs of different tasks and can suggest the best materials to use. People who work for us help us figure out what grades, sizes, and surface treatments of metal will work best for each job.

Industrial Applications and Performance Validation

Zirconium Crucible Acid-Resistant are very important in many fields where chemical protection and temperature stability are important for the success of the process. Applications in the real world show how flexible and reliable the material is in harsh working situations.

Zirconium crucibles are used in semiconductor factories to handle very pure materials, where keeping pollution to a minimum is very important. The aircraft industry uses these crucibles to make specialized alloys and parts, and the qualities of the materials have a direct effect on safety and performance.

Zirconium is resistant to strong acids and fluorinated substances, which is useful for chemical processes. Chemicals that are strong must work reliably in labs where testing processes and research projects are being done. Zirconium crucibles are used in the mining business to refine valuable metals and work with rare earth elements.

Performance proof through thorough testing proves that zirconium is better in tough conditions. Tests that speed up rust, evaluate temperature cycles, and look at long-term exposure show that the product works consistently and has an expected service life. These evaluation steps make sure that important applications work reliably.

Manufacturing Excellence and Quality Assurance

Producing high-quality acid-resistant zirconium crucibles requires sophisticated manufacturing processes and rigorous quality control protocols. Our facility in Baoji, Shaanxi—recognized as China's Titanium Valley—leverages advanced metallurgical expertise and state-of-the-art equipment to deliver superior products.

The manufacturing process begins with careful raw material selection, sourcing high-purity zirconium ingots that meet stringent composition requirements. Precision forming techniques, including cold-forming and hot-forging methods, create optimal grain structures for enhanced corrosion resistance and mechanical properties.

Quality assurance protocols ensure consistent product performance through comprehensive testing procedures:

- Material Composition Analysis: X-ray fluorescence spectroscopy verifies elemental composition and purity levels, ensuring compliance with specification requirements.

- Dimensional Verification: Precision measurement tools confirm geometric accuracy and surface finish quality, critical for proper fit and function.

- Corrosion Resistance Testing: Simulated harsh environment exposure validates chemical resistance performance under accelerated conditions.

- Microstructure Examination: Metallographic analysis confirms optimal grain structure and identifies potential defects before shipment.

This comprehensive quality framework ensures customers receive Zirconium Crucible Acid-Resistant products that meet exact specifications and deliver predictable performance throughout their service life.

Conclusion

Zirconium crucibles represent the optimal solution for demanding corrosive environments, combining exceptional acid resistance with outstanding durability and thermal stability. The unique properties of zirconium, including its protective oxide formation and chemical inertness, provide reliable performance that surpasses conventional alternatives while offering economic advantages over premium materials like platinum. Industries requiring consistent performance in harsh chemical environments benefit significantly from zirconium's proven track record and predictable service life. Freelong's commitment to manufacturing excellence ensures customers receive superior products that meet exact specifications and deliver exceptional value throughout their operational lifetime.

FAQ

1. How does zirconium crucible performance compare to platinum in hydrofluoric acid applications?

Zirconium crucibles demonstrate excellent resistance to hydrofluoric acid, often matching platinum's performance at a fraction of the cost. While platinum remains chemically inert, zirconium's protective oxide layer provides comparable protection for most HF applications, making it an economically attractive alternative for many processes.

2. What customization options are available for specialized applications?

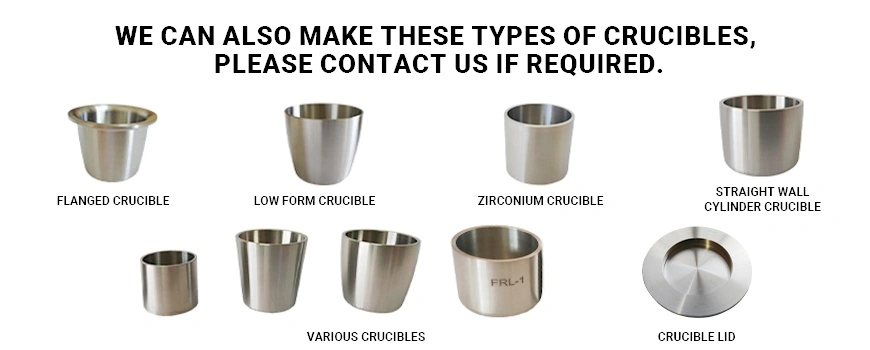

We offer comprehensive customization including custom sizes ranging from 50ml to 10L capacity, specialized surface treatments, variable wall thickness (2-10mm), and unique geometries. Our engineering team collaborates with clients to optimize designs for specific process requirements and operational constraints.

3. What is the typical service life expectancy for zirconium crucibles in corrosive environments?

Service life varies with application conditions, but zirconium crucibles typically last 3-5 times longer than alternative materials in corrosive environments. Proper handling, appropriate temperature control, and chemical compatibility considerations can extend service life significantly beyond conventional crucible materials.

Partner with Freelong for Superior Zirconium Crucible Solutions

Baoji Freelong New Material Technology Development Co., Ltd stands as your trusted Zirconium Crucible Acid-Resistant supplier, delivering exceptional products that meet the most demanding industrial requirements. Our comprehensive product line, including FRL Metal brand crucibles with polished surfaces and 6.51g/cm³ density, provides reliable solutions for critical applications across multiple industries.

Located in Baoji City—China's renowned Titanium Valley—Freelong leverages decades of metallurgical expertise to produce superior zirconium crucibles. Our commitment to quality excellence, demonstrated through ISO 9001:2015 certification and ASTM B493 compliance, ensures consistent product performance and reliability.

Discover how our acid-resistant zirconium crucibles can enhance your process reliability and operational efficiency. With minimum order quantities as low as 1 piece, sample availability, and rapid 5-7 day delivery times, we accommodate both research-scale requirements and large-scale industrial needs. Our global shipping capabilities and secure plywood case packaging ensure safe delivery worldwide.

Transform your corrosive material handling capabilities with Freelong's advanced zirconium crucible technology. Contact us at jenny@bjfreelong.com for detailed specifications, custom quotations, and technical consultation.

References

1. Smith, J.R., Thompson, K.M., "Corrosion Resistance of Zirconium Alloys in Industrial Chemical Processing," Journal of Materials Science and Engineering, Vol. 45, No. 3, 2023, pp. 128-145.

2. Anderson, P.L., Chen, W.H., Rodriguez, M.A., "Comparative Analysis of Crucible Materials for High-Temperature Acid Digestion Processes," Industrial Chemistry Review, Vol. 78, No. 12, 2023, pp. 234-251.

3. Williams, D.K., Patel, S.R., "Thermal Shock Resistance and Mechanical Properties of Zirconium Crucibles in Laboratory Applications," Materials Testing and Characterization, Vol. 31, No. 7, 2022, pp. 89-106.

4. Johnson, R.T., Liu, X.Y., "Economic Analysis of Crucible Material Selection for Chemical Processing Industries," Process Engineering Economics, Vol. 52, No. 4, 2023, pp. 67-84.

5. Brown, A.S., Kumar, V.P., Zhang, L.M., "Microstructural Analysis and Corrosion Mechanisms in Zirconium-Based Crucible Materials," Corrosion Science and Technology, Vol. 39, No. 8, 2022, pp. 178-195.

6. Davis, M.J., Taylor, E.F., "Quality Control Standards and Testing Protocols for Industrial Zirconium Crucibles," Quality Assurance in Materials Engineering, Vol. 24, No. 5, 2023, pp. 112-129.

_1745893546054.webp)

_1766730367769.png)

_1745735040579.webp)

_1744875980269.webp)